Oil magnets

Imagine corralling an aquatic oil spill with a ring of magnets — and then dragging that magnetic fence to some convenient spot where the fuel can be sopped up. As far fetched as this idea may sound, materials scientists began work, this summer, on developing a technology to do just that.

I saw a tabletop demonstration last week that blew me away. Alas, it’s far from being something in which oil companies are likely to begin investing big bucks. One can even imagine a long list of limitations of this technology’s use with spills in rough weather or on the high seas.

But in terms of the science, this concept is way cool.

Mike McHenry of CarnegieMellonUniversity in Pittsburgh introduced a small group of reporters (this year’s Steinbrenner Media Fellows) to the novel application while showing off his lab’s work on magnets. Tiny magnets. Billionth-of-a-meter-scale, novel high-performance iron-cobalt magnets that they make, as needed, in the lab.

While we reporters looked on, a student applied a few drops of mineral oil onto the surface of some water in a Petri dish. That oil served as an early stage, laboratory stand-in for crude oil. Dyed blue, it was easy to see against its watery platform.

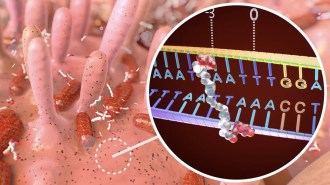

The woman then used an eye dropper to plop a small quantity of a black ferrofluid — oil seeded with untold quantities of the novel nanomagnets — into the same dish. The ferrofluid contained a surfactant (oleic acid) to keep the metallic nanonuggets in it from clumping. Almost immediately, the ferrofluid surrounded and intermixed with the blue oil in the center of the dish.

Afterward, another student placed a strong permanent magnet to the side of the dish. At once, the black nanomagnet syrup floated towards it — dragging along the blue spilled oil.

McHenry acknowledged “you’d need great amounts of this [ferrofluid] to clean up oil spills.” Other groups initially began probing the idea of magnetic attraction as a cleanup technology a decade ago. Their work pointed to the problem of “creating enough of these materials to make cleanup economical,” McHenry said. “But first we needed to show that you can make it work.” Which is what his team is exploring now.

They’ll also need to figure out how to recycle their nanomagnets, “because they are expensive to make,” McHenry notes. “But I think that you could recover them. In fact, we’re working on techniques for scaling up the production of nanoparticles. If they become cheaper, then [nanomagnets] are going to be a potential means of cleaning up oil.”

Once collected and herded to a removal site, what happens to that oil?

“You could skim it off,” McHenry says. “Or we could use a very porous mesh of polymers that oils like to stick to. And there’s a group at MIT that’s developed one that will hold 20 times its weight in oil.”

He was referring to Francesco Stellacci’s team, which a few months ago reported having developed a mesh made from a new manganese-oxide nanowire technology. Tangled and pressed flat, the thin nanowires provide a large surface area to which oil can adhere. Extremely water repellent, the paper-thin mesh selectively sops up oil, leaving water behind.

Stellacci shared a piece of his new mesh about the size of your palm with the Carnegie Mellon lab. Last week, a student then demonstrated the MIT mesh’s adsorption propensity with kerosene that had been poured into another dish of water.

To recharge the mat, the mesh is heated until the oil vaporizes. Trapping and condensing the gases will recover the oil it held.

Right now, the mesh at Carnegie Mellon is only collecting thin oils. In future, McHenry’s group will evaluate how well such an oil sponge deals with other, more viscous hydrocarbons.

I’m fascinated about these innovative approaches to dealing with what has become a huge global problem — oil at sea. The trick, of course, is not just to find a better mousetrap — or oil trap — but to find one that’s affordable, reliable, and environmentally green. Whether the Carnegie Mellon and MIT technologies fill the bill remains to be seen. But both new technologies are clever, and regardless of whether they will tackle crude spills, they likely will find use somewhere in industry, even if it’s just to “green” industrial processes that rely on oily feedstocks or spit out oily wastes.

By the way, these new nanomagnets may see their initial commercialization in medicine. McHenry’s group uses the same nanoparticle recipe for use in ferrofluids to treat cancer. Read more about such magnetic therapy in the Aug. 16 print issue of Science News.

The Magnetic Corral from Science News on Vimeo.

This video shows oil (dyed blue) being poured into tap water. Then a few drops of oil laced with nanomagnets (black) are applied, which quickly spread around the oil. As a magnet moves to the edge of the vessel, the black nanofluid slides to meet it, dragging along the spilled oil.

Source: McHenry Group/Carnegie Mellon