Researchers have designed an entire molecular “assembly line” in bacterial cells that pieces together a kind of alcohol that isn’t normally made by known living organisms. This alcohol could serve as a biofuel that, unlike ethanol, has a high energy density and could be used in gasoline and jet fuel.

While the engineered bacteria are not yet efficient enough to produce biofuel on a commercial scale, the work shows that microbes can be designed to make chemicals that are beyond life’s natural repertoire, the researchers report online December 8 in Proceedings of the National Academy of Sciences.

“Previous metabolic engineering work typically produces compounds that already exist in nature,” says coauthor James Liao, a biomolecular engineer at the University of California, Los Angeles. “Our work here aims to produce compounds that are not synthesized in nature.”

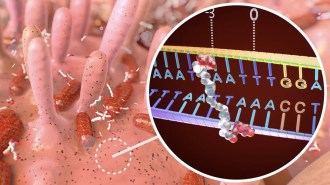

Since the 1970s, scientists have been able to alter cells by inserting a foreign gene into cells’ DNA. That gene carries the genetic code for a protein — perhaps human insulin or a protein that makes plants resistant to pests — that the cells’ machinery will then produce.

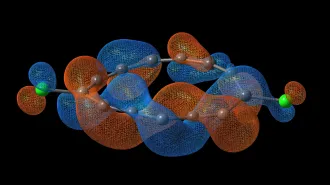

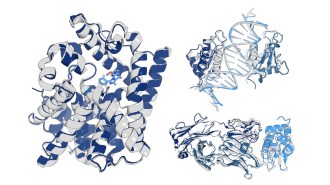

But this engineering approach only works for making proteins, which are large, complex molecules. To make small molecules such as alcohols, cells normally use several proteins as the “robots” in an assembly line that, step by step, converts some other molecule into the desired alcohol.

Liao and his colleagues designed three “robot” proteins that extended metabolic assembly lines in the bacterium E. coli so that it could make relatively large alcohol molecules. When the team inserted the artificial genes encoding those proteins into the bacteria, the bacteria produced alcohols containing between five and eight carbon atoms — ethanol contains only two. Larger alcohol molecules contain more energy than smaller ones and are also easier to separate from the water in which the bacteria live, an important consideration for large-scale industrial production.

Designing artificial genes to make all the robots for such an assembly line is far more difficult than just inserting single genes from different species. This more ambitious form of genetic engineering is often called metabolic engineering, part of a broader field called synthetic biology.

The research is “a major development in synthetic biology, and a marvelous demonstration of how engineering of organisms can be put to practical use,” comments James Collins, a bioengineer at Boston University.

Physical catalysts can also make similar, large alcohol molecules from plant sugars, but Liao says that a biological approach has some advantages. “Biological ways are usually more specific and better controlled. In addition, the biological reaction conditions are at a lower temperature — 30 to 37 degrees Celsius — and lower pressure, as opposed to typical chemical conversions which occur at high temperatures.”

Collins adds that “you just basically feed the bacteria and keep them happy and they chug along and do all the biochemistry.”

These larger bioalcohols could also serve as a renewable feedstock for the chemical industry, Liao says, which currently uses petroleum as a starting material for making everything from plastics to fertilizers.