In Centralia, Pa., the ground is prone to sudden and unexpected collapse. Hot, sulfurous gases waft from vents in the earth, kill trees, drive away wildlife, and sometimes threaten people’s lives. Plumes of smoke rise from cracks in a highway that’s been closed for more than a decade. This once-bustling town isn’t astride the gates of Hell, but instead sits atop an underground coal fire. In 1962, Centralia was home to about 1,100 people. In May of that year, someone set fire to the town’s dump to make room for more trash, a common practice in the region. Unexpectedly, the fire flared for about a month. When workers scraped back the burning refuse, they discovered that the flames had ignited a subterranean coal seam.

The fire continued to burn downward and by August had reached the network of old mine tunnels beneath the town. Carbon monoxide filled the tunnels and closed the mine where many people in Centralia had worked. Over the next 16 years, state and federal agencies spent more than $3.3 million to control the fire, with limited success. In 1983, the U.S. Office of Surface Mining, part of the Department of the Interior, released a study that estimated it might take another $663 million to extinguish the fire. It was far cheaper for the government to buy the town and relocate its businesses and residents.

Today, about 20 holdouts still live in Centralia, even though the government condemned their homes more than a decade ago. The last church in town has been razed, but its cemetery remains. The town is now so small that the U.S. Postal Service is taking away its zip code.

Stubborn underground fires like that in Centralia aren’t uncommon in coal country. Any region with enough coal for a mine is at risk. There are dozens of coal fires burning out of control in Pennsylvania alone; worldwide, there could be hundreds of thousands. Some smolder deep within abandoned mines; others blaze forth in exposed seams of coal. Like forest fires, coal fires can be sparked either by natural phenomena such as lightning or by people’s carelessness.

Beyond their potentially devastating effects on mining communities, coal fires change the landscape and damage the environment.

Fighting fire

Coal fires can be difficult to extinguish. In Centralia, for instance, workers tried to smother the fire with fly ash–a byproduct of burned coal–but failed. Then, they attempted to dig a trench to isolate the burning coal, but the fire had advanced farther than they had expected.

The mine tunnels, as well as pre-existing fractures in the rocks, permit airflow to the fire, says Daniel H. Vice, a geologist at Pennsylvania State University’s Hazelton and Schuylkill campuses. The configuration of the coal seam didn’t help matters, either. The layers dip below the surface at angles between 35 and 60, making it difficult to dig trenches deep enough to get below the fire to isolate it.

The Centralia fire is an example of why it’s important to attack coal fires early, says Steve R. Jones, a geologist at Pennsylvania’s Bureau of Abandoned Mine Reclamation in Harrisburg. If firefighters arrive before a coal fire spreads across about 1 hectare–an area about 2.5 times the size of a football field–then the blaze can typically be extinguished for less than $500,000, he estimates. If the fire burns for a year or so and covers 5 hectares, then firefighting costs often exceed $1 million.

With funding from the U.S. Agency for International Development, Jones and a few colleagues from Pennsylvania, West Virginia, and North Dakota developed a training course that would help geologists worldwide analyze a coal fire to determine the best way to extinguish it.

For example, Indonesia suffered a spate of forest fires in 1998, when an El Nio brought drought to large regions of the western Pacific. Dry conditions allowed many agricultural fires to escape control, and some of those blazes ignited deep beds of decaying plant matter on the forest floor (SN: 11/9/02, p. 291: Wildfire Below: Smoldering peat disgorges huge volumes of carbon) and subsequently lit coal seams.

Late in 1998, in the first stages of a 3-year pilot project, the scientists and local geologists conducted a coal-fire census and found 84 such fires still burning along a 120-kilometer highway that rims Borneo’s eastern shore. That figure, extrapolated to the entire Indonesian coal-producing area, suggests that the country may have had up to 100,000 coal fires at that time. During the El Nio, the carbon dioxide and other greenhouse gases from those conflagrations probably rivaled the pollution spewed by the country’s automobiles, says Jones.

He and his colleagues have trained about 100 students, who now are educating other Indonesians in firefighting techniques. Jones described the project and its early results in Denver at February’s annual meeting of the American Association for the Advancement of Science (AAAS).

A simple recipe

Coal fires, like all blazes, need three ingredients: oxygen, fuel, and heat. The key to putting out a coal fire is to remove one or more of those ingredients from the mix, says Jones.

Consider oxygen. Trying to smother a coal fire with a thick layer of material such as fly ash–chosen simply because it’s available in large quantities at low cost from coal-fired power plants and other industries–just doesn’t work, says Jones. Long-worked mines are typically made up of air-filled corridors with pillars of coal left to support the roof. That coal can smolder even when the air contains only 2 percent oxygen, about one-tenth the concentration in the atmosphere.

When those pillars burn through and collapse, the ground above the mine subsides. Cracks in the ground or any covering then create new routes for fresh air to reach the fire, which flares up again.

Pumping water into a burning coal fire to smother and cool it doesn’t often work, either, because mines are voluminous and the rock around them is so fractured that the water doesn’t stay in place. Also, most mine fires burn the coal or carbon-rich rocks in the roof of the mine’s tunnels, which are the last areas to be inundated with rising water.

The best way to put out a coal fire currently, says Jones, is to deprive it of fuel. Firefighters dig a moat to isolate the burning coal and then fill the trench with noncombustible material, such as rock. Sometimes, as an added precaution, the encircled coal can be spread atop the ground and doused with water or simply left until it cools.

These excavation techniques are currently being used to reopen a portion of Boyce Park in western Pennsylvania’s Allegheny County. About 2 hectares of land there reignited in 1989, more than 25 years after officials thought they had smothered the coal fire at a site more than 500 m away with a thick layer of clay. The $1.2-million reclamation project should be completed this summer, says Jones.

Scientists are also investigating more-advanced firefighting methods, such as the strategy described at the AAAS meeting by Ann G. Kim of the National Energy Technology Laboratory in Pittsburgh. The high-tech approach reduces the fire’s heat and oxygen supply.

In a field test at a coal fire that’s been burning for 30 years, Kim and her colleagues pumped a slurry of frozen carbon dioxide and liquid nitrogen into a smoldering pile of waste coal. When this –180C mixture hit the 350C coal, the carbon dioxide and nitrogen vaporized, says Kim. The process absorbed extraordinary amounts of heat. Furthermore, the rapid expansion of cold gases forced hot, oxygenated air from the waste pile and replaced it with chemically inert nitrogen and carbon dioxide. Measurements showed that temperatures in a borehole close to the slurry injection dropped to around 100C, near the temperature at which a coal fire can’t sustain itself. In the test, the fire wasn’t completely extinguished, says Kim, because the researchers didn’t have enough of the quenching slurry on hand.

Heat attack

The prodigious heat generated by coal fires affects the landscape in small ways and large, and in time frames both short and enduring.

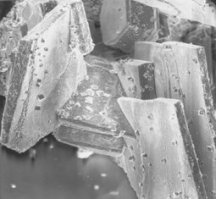

Some of a coal fire’s most unusual mementos are the minerals that condense from superheated gases spewing from the ground, says John H. Barnes of the Pennsylvania Geological Survey in Middletown. He and his colleagues have discovered several new crystal forms of those minerals at Pennsylvania coal fires.

For example, there’s downeyite, a transparent crystalline form of selenium dioxide. The mineral was discovered at vents above a coal fire near Glen Lyon, Pa., and named for Wayne F. Downey Jr., the geologist who figured out a way to get the substance back to the lab intact. Downeyite attracts water so well that it pulls moisture from the air and then dissolves into it. “In less than a minute at normal conditions, the crystals turn into a puddle,” says Barnes.

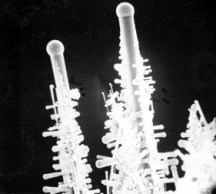

Another interesting Pennsylvania-grown mineral was discovered on a burning pile of waste coal in Forestville. The crystal is an as-yet-unnamed type of germanium sulfide that forms long, straight rods with small bulbs at the end. “They look like little matchsticks,” Barnes notes. Often, smaller matchstick-shape crystals sprout from the rods, he adds.

Most of the minerals that condense from coal-fire gases are made up primarily of elements that were present in the coal only in trace amounts, says Barnes. Carbon, by far the largest constituent of coal, typically wafts away as carbon dioxide and carbon monoxide.

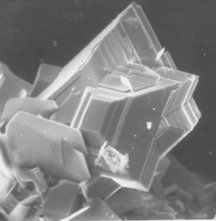

A longer-lasting product of both underground and surface coal fires is a rock that geologists call clinker. It forms when the heat bakes surrounding rock layers into a bricklike rock, says Ed Heffern, a geologist with the Bureau of Land Management in Cheyenne, Wyo. Clinker associated with deep mine fires often goes unnoticed because it remains underground, but in the West, where coal fires have occurred naturally in exposed beds of coal for millions of years, the reddish rock dominates some landscapes.

That’s certainly true in the Powder River basin of Montana and Wyoming, a region that currently produces more than one-third of the coal mined in the United States.

The river, which Lewis and Clark named the Redstone River because clinker boulders line its channel, earned its current name from the sulfurous smell of natural coal fires that reminded explorers of burning gunpowder. About 4,100 square kilometers of the hills, ridges, and cliffs there are topped with clinker that’s up to 60 m thick, says Heffern. Between 30 and 50 billion tons of coal must have burned to produce these outcrops.

Because clinker is more erosion-resistant than unbaked sediments are, it can protect the rock layers beneath it for a longer period of time. Radioactive dating of minerals in the clinker outcrops suggests that some of the region’s coal fires occurred as many as 2.8 million years ago. Some clinker boulders in the Powder River itself may have been baked as many as 4 million years ago. In the era before humans trod the landscape, many of the region’s coal fires were probably sparked by lightning, others by wildfires, and some by spontaneous combustion during hot, dry conditions.

Dateline, 2250?

There are 36 active coal fires in Pennsylvania, and most have been burning about 40 years or so. In recent decades, new approaches to fire fighting in the state have squelched most coal fires before they raged out of control.

Almost all the active fires are located in remote areas and, as such, will be permitted to burn themselves out. It’s difficult to estimate how much coal tonnage is going up in smoke–and greenhouse gases–each year, says Jones. “That would make a good university research project,” he says.

Progress of the Centralia fire, which spread underground from its source along four separate fronts, is sporadic, says Vice. Today, only two fronts are still active. Months of no apparent advance are interspersed with surges that occur, for example, when oxygen reinvigorates the fire. For example, the temperature of gases taken from a borehole along the Centralia fire’s western front last December was approximately 375C, says Melissa A. Nolter of Penn State, Schuylkill. Measurements she took at the same location this year in mid-March topped 430C, documenting that the fire is moving westward.

Of Pennsylvania’s coal fires, Centralia’s is by far the largest, says Jones. During the past 4 decades, it’s advanced, on average, almost 23 meters per year and now underlies about 1.8 square kilometers. Geological maps of the area show that coal sits beneath another 12 square kilometers adjacent to the fire. Jones estimates that if the fire continues to burn at its current rate, it may take about 250 years before the hungry demon runs out of fuel.

****************

If you have a comment on this article that you would like considered for publication in Science News, send it to editors@sciencenews.org. Please include your name and location.