Peter Parker is lucky he was bitten by a spider and not a silkworm. Not only does “Spider-Man” have way more superhero panache than “Silkworm-Man,” but of all the silks made by various creatures, spider silk is the standout. Exceedingly strong, yet elastic and lightweight, spider silks are ideal for a range of materials, from bulletproof vests to scaffolding for growing cartilage.

Scientists are coming closer to unraveling spiders’ secrets with the hope of producing piles of the fiber to put to good use. While there’s progress in understanding spider silk genes and proteins, challenges persist. Silkworms were domesticated centuries ago and are content munching mulberry leaves in close quarters, but most spiders are both predators and loners. When crowded together, they often become cannibalistic, making them difficult to rear en masse. And while a single silkworm cocoon can yield 600 to 900 meters of silk, a spider gives up after spinning out only 130-odd meters or so.

So scientists are trying to coax spider silks from other creatures, experimenting with inserting silk genes into bacteria, tobacco plants and goats. (No pigs yet, but making a silk purse from a sow’s ear may not be as crazy as it sounds.) Other researchers are investigating the silken threads made naturally by insects such as bees, wasps and ants.

Once scientists can make mass quantities of silk cheaply—which means perfecting not only the raw material, or silk “dope,” but also the best way to spin it—then the threads may find their way into a panoply of products. Part of the allure of mastering natural silks is the potential to make a strong, elastic fiber at room temperature and without harsh chemicals. This promise of green chemistry enthralls scientists, who say silk offers an environmentally friendly alternative to the petroleum-based fibers of today.

“It’s really ideal,” says Randy Lewis of the University of Wyoming in Laramie. “If you can mimic it, you can eliminate an awful lot of the problems you have with all the man-made fibers that are currently available.”

The best understood and most explored silks are those made by silkworms, the caterpillar of the silk moth, Bombyx mori. Domesticated some 4,500 years ago, the silkworm can no longer survive—and is no longer found—in the wild. Using a three-step process—make proteins, add glue, spin—the silkworm spins itself a shroud from a single continuous thread that may be more than half a mile long.

The silkworm is easily reared, and its silk has been used for centuries. Today silkworm silk is a more popular surgical suture than collagen. But caterpillar silk has its problems. The silkworm encases its two main silk proteins in a coat of sericin, a gluelike protein that seals the cocoon together. When used as sutures or for other medical applications, this sericin glue can provoke an immune response in people and therefore must be coated over or removed. And silkworms spin just one kind of silk.

“We love the silkworm,” says David Kaplan of TuftsUniversity in Medford, Mass. “But spider silk is so diverse—we want to exploit that.”

The full orchestra

If silkworms are one-note Johnnys, spiders are silk virtuosos. A true spider—a member of the 39,000-species–strong order Araneae—makes up to five kinds of silk fibers. Multiple abdominal glands, the shape and number of which vary across species, allow spiders to produce more than one kind of silk at a time—and mixing threads and proteins from different glands is not uncommon, says Catherine Craig of Harvard University’s Museum of Comparative Zoology.

Spiders make egg-case silk, prey-wrapping silk and of course web silk, which comes in several varieties, such as scaffolding, sticky or structural. (The more ancient tarantulas, which do not construct elaborate webs but do use silk to wrap their eggs and line their burrows, were recently shown to produce silk from spigots on their feet. This finding raised the possibility that abdominal-gland silk is a more recent evolutionary invention and that feet spigots came first.)

Spiders have been silking it up for more than 350 million years—a skill that was probably instrumental in their diversification, Craig says. Spiders rank seventh among all animal species in global diversity, beat only by certain insect orders and the mites and ticks.

The most studied spider silks come from the golden silk spider, Nephila clavipes, and the European garden spider, Araneus diadematus. Dragline silk, which these orb-spiders use in the outer rims of their webs and as a safety bungee when dropping or falling from high, has been investigated the most. It is both superstrong—meaning it can support tremendous weight—and supertough—meaning it can absorb a lot of kinetic energy before breaking. An inch-diameter fiber made of dragline spider silk could reel a 747 from the sky, Lewis says. The silk isn’t just tougher than Kevlar or as strong as steel; it is also light, and thus an excellent material for things like body armor and parachute cords, or for tethering planes to an aircraft carrier.

Spider silks also seem to be friendly inside the human body. Studies suggest that spider threads don’t elicit an angry response from the immune system, says TuftUniversity’s Kaplan, who published a review of spider silk applications in the May Trends in Biotechnology. Kaplan cites experiments with ultrathin films made of spider dragline silk, which could be used for wound dressings.

Spider silk is also being used to make porous gels and sponges, which can be seeded with tissue or bone cells that grow around a silk lattice that gradually biodegrades. Researchers have had success growing the nerve cells known as Schwann cells on spider-silk threads, pointing to the possibility of artificial nerve grafts. Scientists have also had recent success engineering tiny capsules with spider silk. The capsules can be broken down by specific enzymes, which would allow doctors to precisely control the release of drugs within the body, the researchers reported last year in Advanced Materials.

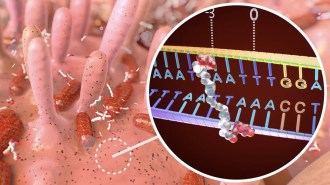

While spider silks hold promise in numerous applications, scientists are still untangling the intricate set of building blocks and genetic instructions that underlie each thread. Each silk seems to have a corresponding gene, and scientists have deciphered the “letters” of code for 11 silk genes so far, says Lewis. Within each gene the arrangement of code is complex. Repeated stretches of code contain protein-making instructions, but are peppered with introns, or stretches of DNA that don’t contain directions. This genetic complexity has probably contributed to the diversity of silks and their stability in the spider lineage, Kaplan says.

Pinch spinners

But this genetic ungainliness has also made it difficult for genetic engineering workhorses, such as the bacterium E. coli, to pump out spider silk proteins in the lab. So scientists are now trying to tease silk from a menagerie that includes hamsters, yeast, goats, mice and transgenic silkworms. Plants such as potatoes, tobacco and alfalfa have also been recruited.

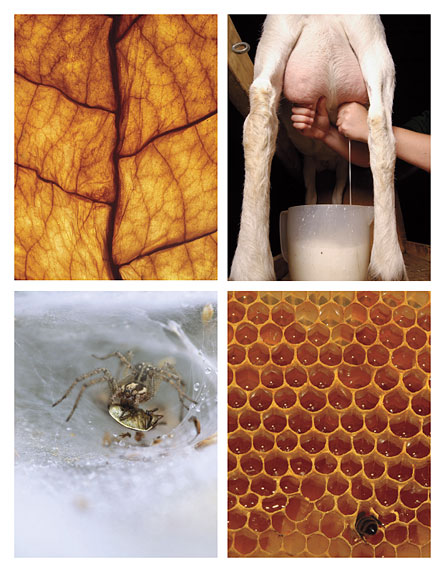

Lewis has collaborated with scientists at the Canadian firm Nexia Biotechnologies, part of the team that spliced spider silk genes into bovine cells in 2002 and later into goats. Today, transgenic goats roam at the University of Wyoming. While present in every goat cell, the spider silk genes are turned on only in the mammary glands, yielding goat milk laced with silk proteins. While promising, the yield is still low, Lewis says. A gallon of milk may have only 60 grams of silk, which means it would take about 600 gallons of milk to make one bulletproof vest. And there are still problems with purifying the proteins. After a few grams of silk have built up, the milk starts coagulating, perhaps because the silk proteins are binding to proteins in the milk, Lewis says.

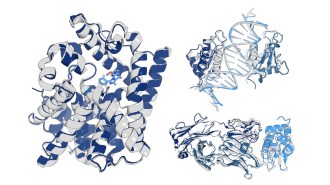

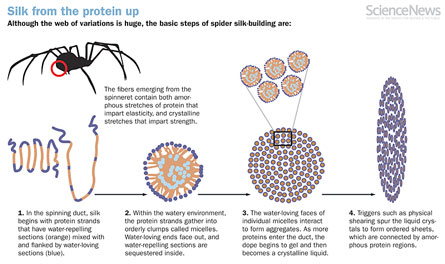

Silk proteins come in a rich array of structures, but generally, the molecular structure of silk consists of regions of protein crystals separated by less organized protein chains, Kaplan says. As the spider dumps more and more silk protein into the spinning duct, the protein forms a gel and gradually organizes into a liquid crystalline phase. Then, in a feat that would make Rumpelstiltskin jealous, the spider pulls the fiber from its spinneret. The fiber shears in such a way that crystals form and, in one-tenth of a second, the dope goes from liquid to solid.

“It is truly an amazing process,” Kaplan says. “It is fast and efficient, and at once it is insoluble in water, even though it is made in water.”

Scientists are making headway in analyzing the ingredients and mechanical properties of various spider silks, but many secrets remain within each gossamer strand. John Gosline of the University of British Columbia in Vancouver, Canada, and his colleague Ken Savage recently compared the dragline silk of the golden silk spider with that of the European garden spider. The silks behaved almost identically when dry, but when wet the golden spider’s silk was almost 10 times stiffer, behaving more like a spring than a stretchy rubber band. The difference is probably because of a protein building block, the amino acid proline. Garden spider silk has four times more proline, which may break up the silk’s crystalline sheets, giving it more stretch, the researchers report in two papers published in June in the Journal of Experimental Biology.

Spiders are particularly adept at spinning silk to suit a specific purpose, says Gosline. The repeated sections of amino acids in dragline silk, for example, differ from the sequence of amino acids in flagelliform silk, the superelastic thread used in the spiral section of the web.

The very same silk, from the very same spider, can have different properties if taken by force—silked or “milked”—than if it is released by choice, Gosline notes. Spiders can’t eject silk, Spidey-style—they must pull it out with their legs or attach it to something and move away. They also seem to have some kind of brake in their spinnerets that allows them to control the silk’s flow, like applying a thumb to a water spigot. If researchers anesthetize a spider, they can pull out silk with very little resistance, while a spider that has just begun to be “milked” might resist with a force several times its body weight, resulting in a silk that is much stiffer and stronger, but less extensible, Gosline says.

“Spiders are amazingly adept at using their silk in subtle ways, adjusting it for load size and purpose,” he says. “We don’t even know the range.”

Concocting the right mix of silk proteins is one thing; spinning them into silk is another. Techniques have been developed to purify and spin silk, but none have matched the spider at her loom.

In order to develop better spinning techniques, scientists need silk and lots of it. Since spider farms are out, engineering alfalfa or tobacco plants to make silk holds promise as a relatively cheap means to make lots of it. If goats can make silk proteins only in milk, maybe plants like tobacco could be engineered to make silk proteins in one concentrated and easily harvestable spot.

Many plant seeds have a hefty dose of nutritive tissue, much like the yolk of an egg, which nourishes the young plantlet. Getting plants to replace that tissue with silk proteins may be the best way to mass produce the fiber, says Tara Sutherland, who works in the entomology section of Australia’s Commonwealth Scientific and Industrial Research Organisation in Canberra. At the moment though, Sutherland is focused on silks made by insects, which craft many different silks, although only one kind each. Sutherland has zeroed in on the silks of bees, wasps and ants.

Silkier than honey

“Imagine a hive and each new generation of bees being wrapped in a silken cocoon,” Sutherland says. “If you remove the wax and look where the bees were raised, there is silk—beautiful sheets of golden silk.” In addition to protecting each larval bee in its cell, the silk might add structural support to the hive and prevent the wax from getting so warm that it melts. Sutherland speculates that the buildup of silk in a hive’s cells may be what eventually drives the insects to seek a new hive. “Eventually there’s just no room.”

Sutherland is also investigating weaver ants, which use silk to stitch leaves into nests. It seems that only the baby weaver ants make silk. The adults hold onto and maneuver the little larval silk-makers for desired placement.

The general structure of most silks made by the hymenopteran insects with stingers—the bees, hornets and most wasps—has been known for some time and is very different from other silks. Rather than assembling crystalline sheets, these silk proteins form interlocking helices known as coiled coil silks—like spiraled pasta versus flat sheets of linguine, says Sutherland.

After the sequencing of the honeybee genome, Sutherland’s team went hunting for honeybee silk genes and found four, each coding for a different coiled coil protein. Then the team looked for silk genes across a range of hymenopterans: in the bumblebee, weaver ants, bulldog ants and some stinging and non-stinging wasps.

Parasitic wasps and sawflies—the hymenopterans without stingers—also make silk cocoons, but it turns out that they use the flat-sheet format, Sutherland and colleagues reported in Molecular Biology and Evolution in November 2007. This difference suggests that the coiled coil silks were invented roughly 155 million years ago, after the split between the stingers and non-stingers, she says. The arrival of coiled coil silks may have even contributed to the social nature of these insects, making hive-living more feasible.

Bee and ant silk is both tougher and more stable than silkworm silk, says Sutherland. But so far, nothing beats spider silk. Nevertheless, the simplicity of the four genes and four proteins that bees use makes their threads an attractive alternative to the more complex silk of spiders.

“It’s a wonderful material,” Sutherland says of spider silk. “But it is very difficult. The proteins are big and repetitive.” And bee silk doesn’t seem to make lab bacteria stumble, she says. So watch out villains—Spidey may one day be upstaged by other silk spinners. Here’s to Ant-Man, Lacewing and The Bee.