Spiders spin stronger threads with nanotubes

Carbon sprays lead to silk tougher than any other fiber

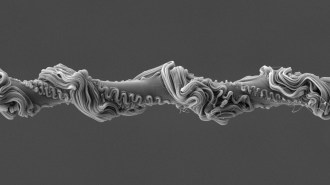

STRONG SPINNER Spritzing spiders with graphene flakes or carbon nanotubes boosts silk strength and toughness.

Gucio_55/Shutterstock

Sorry, Kevlar. Spider silk loaded with carbon nanotubes may be the burliest fiber around.

When spritzed with the tiny tubes, spiders spin superstrong, supertough strands of silk. These hardy threads are the toughest fibers ever created, researchers report online April 25 at arXiv.org.

Such fibers could one day replace the heavy steel cables that haul elevator cars up skyscrapers, says materials scientist Mato Knez of CIC nanoGUNE, a research center in San Sebastian, Spain. But that day is still a long way off, says Knez, who wasn’t involved in the work.

“It will probably take another 20 years or more before people can produce a real product out of it,” he says.

Scientists have been jazzing up spider silk for years. It’s a good material for experimenting, says study coauthor Nicola Pugno, an engineer at the University of Trento in Italy. Silk is naturally strong, lightweight and tough — like a rubber band, it’s resilient. Stronger fibers, such as those made from graphene and carbon nanotubes, tend to be brittle, like glass.

Researchers have added titanium to spider silk to boost toughness, carbon nanotubes to silk to conduct electricity and nanocrystals to silk to make it glow. But until now, scientists have tinkered mostly with the silk, not the spider, Pugno says. He wanted to figure out how to make spiders spin souped-up threads themselves.

So Pugno and colleagues spiced up the diets of 15 captured Pholcidae spiders. First, the team sprayed the spiders and their homes with watery solutions of graphene flakes or carbon nanotubes. Graphene, a thin sheet of linked carbon atoms, can be rolled up like tiny cigarettes to form carbon nanotubes.

After the spiders started spinning, the researchers collected the silk and analyzed its strength, toughness, and chemistry. Strong materials can take a beating, but a crack can make them shatter. Tough materials are easier to crack, but they’ll bend before breaking.

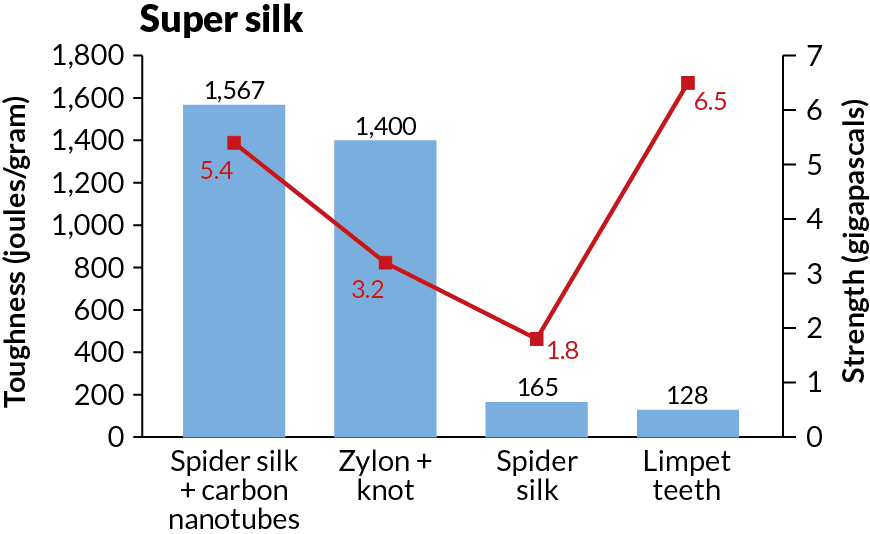

Both graphene and carbon nanotubes upped the strands’ strength and toughness, though carbon nanotubes tended to give silk a bigger boost. Strands reinforced with nanotubes broke the record for toughest fiber, surpassing even knotted Zylon, a synthetic fiber used in tennis rackets. (Pugno has previously shown that twisting a fiber into knots can increase its toughness.)

But the researchers don’t know exactly how their technique works.

The fibers bore chemical signatures of graphene or carbon nanotubes, which could mean the spiders ate the high-tech materials and wove them into their silk. Alternatively, the sprayed materials could have stuck to the silk’s surface.

But a nanotube coating doesn’t seem to explain the silk’s new-found strength.

“Eating is the most plausible scenario,” Pugno says, “but this is still an open question.”