Vision Quest

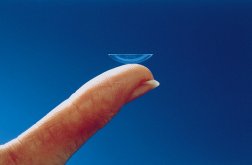

New materials promise to make contacts more comfortable and convenient

“Nobody move! My contact lens popped out!”

In the early days of hard contact lenses, many wearers found themselves uttering this alarm, then dropping to their hands and knees to search for the wayward piece of plastic. Of course, the lens always seemed to get lost in a room with wall-to-wall shag carpeting and guests parading about in high heels.

Nowadays, the command for a whole room to freeze is hardly ever heard. The advent of soft contact lenses, which cling to the eye’s surface, made this scenario less and less likely. The flexibility of soft lenses also made them easier to get used to and more comfortable to wear. New and anticipated improvements in lens materials promise to further increase the comfort and safety of contacts. Other innovations in lens design and materials could make contact lenses available to a wider range of people with less-than-perfect vision.

Hard plastic

Modern contact lenses appeared on the market in 1949, says Keith Parker, general manager of Essilor Laboratories’ contact lens division in Denver. Those lenses were made from a hard plastic called polymethyl methacrylate, or PMMA, that allowed no oxygen to reach the area of the cornea under the lens. Imagine sticking your glasses directly to your eyeballs—clear vision but discomfort and awkwardness.

Bausch and Lomb introduced the first soft contact lens in 1971. This development signaled “a revolution in comfort to the patient,” says Buddy D. Ratner, a materials scientist at the University of Washington in Seattle. Soft contacts rely on plastics called hydrogels, polymers that soak up a lot of water. The first hydrogel used for contacts was hydroxyethyl methacrylate, or HEMA. Lenses of this material can hold 38 to 70 percent water by weight, which makes the lens soft and flexible.

The water carries dissolved oxygen through these lenses to the eye surface, says John McNally, an optometrist and head of clinical affairs at CIBA Vision in Duluth, Ga. “The eye needs oxygen to keep the tissue healthy.”

A high water content also makes soft lenses more comfortable. People blink about every 5 seconds, says McNally, and a wet lens surface reduces the friction between the eyelid and the plastic.

For 20 years, most of the innovations in soft lenses boosted the hydrogel’s water content. This approach has its limits, though, McNally says. Too much water makes the lens fragile and difficult to handle. Contact lens wearers become frustrated trying to slide a floppy lens from a fingertip to an eye.

Moreover, even if a lens could be made of a layer of pure water, it wouldn’t get enough oxygen to the eye, according to McNally. Researchers decided to find new polymers that could allow greater oxygen flow.

A few years ago, a collaborative effort by CIBA Vision, Novartis in Switzerland, and the Cooperative Research Centre for Eye Research and Technology in Australia developed a new polymer called lotrafilcon A. It contains a modest 24 percent water yet allows six times as much oxygen to pass through as the best of the HEMA hydrogels do (SN: 10/11/97, p. 236).

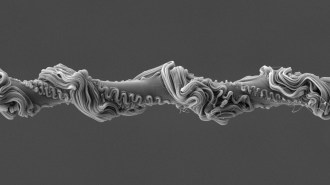

Lotrafilcon A consists of interspersed micrometer-size bits of two different plastics. One material, a hydrogel, lets water and ions reach the eye surface; the other, called fluorosiloxane, channels oxygen. The combination is as transparent as a conventional contact lens.

The ability of a material to convey oxygen relative to its thickness is called transmissibility. Lenses should have a transmissibility of at least 90 barrers for oxygen, according to researchers at the University of California, Berkeley and Indiana University in Bloomington. Typical soft contact lenses have a transmissibility of 20 barrers. Lenses made with fluorosiloxane have a transmissibility of 175 barrers.

“The dream of a soft hydrogel that delivers sufficient oxygen has finally been realized with this material,” says Ratner. Fluorosiloxanes are currently under review by the Food and Drug Administration for sale in the United States.

The materials are already available in 16 other countries as 30-day extended-wear and daily-wear lenses, which are removed every night and cleaned.

Cleaning lenses

Some people find it difficult to keep hydrogel lenses clean, opening up the potential for nasty eye infections. Lenses of fluorosiloxane provide less of a problem than the others because proteins don’t stick well to them. Wearers of most other types of soft lenses have to use enzyme solutions to remove protein deposits that the hydrogels attract.

Optometrists encourage many patients to use daily disposable lenses, which are thrown away after each wearing. Automated manufacturing has lowered the cost of lenses enough to make this practice feasible.

Most longer-lasting contact lenses are made by clamping together plastic molds for the front and back surfaces of the lens. A thin layer of liquid polymer is squeezed into the remaining space and either cured with UV light or baked to turn it solid. Then, all the excess molecules are washed away and water is added.

For its daily disposable lenses, CIBA Vision uses a material called nelfilcon A, a polyvinylalcohol. The material allows the manufacturing process to be fully automated, says McNally. The lenses emerge with the water already incorporated. Because it takes only a few minutes to manufacture each lens, the process is efficient and a pair costs only about $1.

CIBA uses molds made of transparent quartz glass, which can be reused, unlike the plastic molds used for hydrogel lenses. A drop of nelfilcon A is placed onto one half of the mold, and the complementary half is suspended a few micrometers away. A circular mask is placed around the edge of the lens, and ultraviolet light is shined through the molds to cure the polymer. The mask blocks the UV light and creates a precise, smooth rim.

This allows for a consistent shape with an edge half the thickness of other lenses, says McNally. A thinner edge reduces what’s known as edge sensation, discomfort caused by the eyelid rubbing against the lens rim.

Lens specs

A lens is about 14 millimeters in diameter, but only the center portion, 8 mm across, is shaped to correct vision. Lenses for nearsighted people are thin in the center but get thicker at the edge of that center zone. To correct farsightedness, lenses have a thick center that tapers down at the edge of the optical zone.

Because standard contact lenses are free to rotate as they sit on the eye’s surface, they can’t correct for astigmatism, a condition in which the cornea doesn’t have a spherical shape. Astigmatic eyes require toric lenses, which have different lens powers along different axes of vision.

Recently, lens designers have produced contacts for astigmatism. By making the outer part of the lens, called the carrier portion, thicker on one side than the other, the manufacturer can ensure that the correction stays in line with the axis of irregular vision. As the wearer blinks and the lens moves, the thicker, heavier part stays at the bottom, ensuring that the lens is oriented correctly. These contacts have become widely available within the past 2 years, says McNally.

Another problem that contact lens makers are tackling is presbyopia. “When you hit your 40s, the crystalline lens [in the eye] cannot change focus quite as readily,” McNally explains. This leads to the phenomenon of a person’s arms suddenly not being long enough to hold the newspaper at an acceptable reading distance. So, around this time in life, people tend to find reading glasses, bifocals, and even trifocals perched upon their noses.

Traditional bifocal spectacles usually have a small area in the bottom of the lens, known as the addition portion, that provides up-close focusing. When first introduced 20 years ago, bifocal contact lenses had the addition portion in the center and distance power in the periphery of the optical zone. The wearer would essentially use both powers at the same time.

However, there were drawbacks to this design. “You could get ghosting,” says McNally. That is, looking at a car in the distance would produce two cars: one in focus and one blurry.

Two newer designs provide better correction for people with presbyopia. In September 1999, CIBA Vision introduced progressive soft contact lenses, similar to the no-line spectacles that have a gradient of different powers rather than an abrupt transition from distance to up-close focusing.

With the progressive lenses, the ghosting is “so muted that it’s not noticeable,” says McNally. “It’s less of a distraction.” The visual acuity is not as sharp as through spectacle lenses, he says, “but people have been very satisfied.”

The progressive lenses are made out of a 55-percent-water hydrogel known as vifilcon A, the same material that CIBA Vision uses for its monthly and weekly lenses and lenses for astigmatism.

Last April, Vistakon in Jacksonville, Fla., introduced a bifocal lens with five concentric rings of different optical powers. It brings many distances into focus at the same time, says John McKeegan, a Vistakon spokesman.

Implantable contact

Lens researchers are also looking toward such futuristic possibilities as the implantable contact, which would act as an artificial cornea. Implants would serve as a less permanent alternative to corrective surgical techniques such as radial keratotomy or photorefractive keratectomy.

Surgeons are already implanting polymer rings that reshape the cornea (SN: 9/11/93, p. 172).

“Instead of sculpting tissue, we’re adding on. It’s another alternative that we’re very excited about,” says McNally. Unlike a surgically reshaped cornea, implants could be adjusted if a patient’s prescription changed over time.

Researchers are also working toward intraocular lenses that would completely replace the eye’s natural lens. At present, during cataract surgery, the eye’s lens is replaced with an artificial one. This replacement has a fixed focus, however, and the muscular iris—the colored part of the eye—cannot squeeze the lens to change its focus as it did with the natural lens. The patient has to wear glasses to further correct his or her vision.

“We’re looking for implant lenses that can change focus just like the original lens,” says McNally. “It’s really difficult to invent and develop a good contact lens,” he concludes. The technology has come a long way since 1887, when the German ophthalmologist Adolf Fick made the first contact lenses from glass (ouch!).

Safer, more comfortable materials and designs are now leading the quest for 20/20 vision into the future.

Letter to the editor:

This article says, “The muscular iris—the colored part of the eye—cannot squeeze the lens to change its focus as it did with the natural lens.” There are two errors in this description. First, the ciliary muscles, not the iris muscles, focus the lens (focus and pupil size are controlled independently). Second, the ciliary muscles don’t squeeze the lens. Rather, their contraction loosens supporting fibers that permit the lens to bulge (increasing curvature and power) through built-in elastic shape recovery.

Jeremy M. Harris

Worthington, Ohio