Scientists have figured out a new way to strong-arm some catalysts, tying the chemical compounds down and then, as needed, unleashing them with brute force. The research, published online April 6 in Nature Chemistry, could lead to coatings that heal when scratched or new fluids for making moldings or microchips. The work also offers a way to monitor stress in materials found in products such as bike helmets.

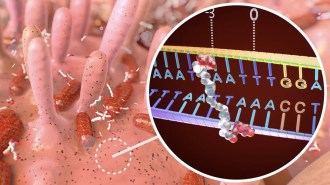

A catalyst’s job is to speed up or slow down a reaction in everything from car engines to cells. But to do so, an area known as the active site has to be exposed. In materials science, catalysts are often spurred into action with heat, UV light or a change in pH. In the new study scientists used the ultrasonic force released by bursting bubbles to unleash two catalysts that had been bound in chains of polymers.

“This has a lot of materials applications,” comments chemist Alshakim Nelson of the IBM Almaden Research Center in San Jose, Calif. “It offers a lot of control.”

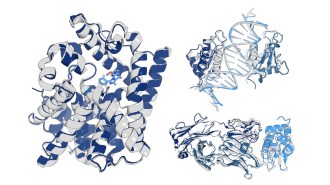

A team of researchers led by Rint Sijbesma of the Eindhoven University of Technology in the Netherlands began by experimenting with known catalysts, including one based on the versatile ruthenium. This platinum-related metal’s catalytic properties were explored by Robert Grubbs, who shared the Nobel Prize in chemistry in 2005 for his work.

The scientists started with catalysts that included a metal — either ruthenium or silver — sandwiched between molecules known as carbenes. Carbene-metal combinations are often used because they are stable but can be activated as necessary.

To each carbene, the scientists attached a long polymer chain, so the latent catalysts sat at the center like a watch face with two extended straps. The chained catalysts were mixed in flasks with a particular set of chemicals. Then the researchers stuck an ultrasound probe into each flask.

The force generated by the ultrasound stressed the polymer chains, which extended.

“It’s just like in a game of tug-of-war,” Sijbesma says. “There is drag on every piece of the chain, and at the center of the chain the force is the highest.”

As the chains extended, a break eventually occurred at the weakest point, between the polymer chain and the carbene. This exposed the active site of the catalysts — in one instance the ruthenium and in the other the carbene. Thus, the reactions proceeded at a time precisely dictated by the ultrasound.

After one hour with the ultrasound probe in a flask containing benzyl alcohol, vinyl acetate and the silver-based chained catalyst, 65 percent of the reactants converted to the desired product, benzyl acetate. Only 3 percent did so in control flasks that received no sonification, the researchers report. The yield was lower in the flask with the ruthenium-based chained catalyst.

The yield will have to improve for the reactions to be less wasteful, Nelson says. Chemists typically strive for a 99 percent conversion rate, which costs less time and money. But fine-tuning the setup may result in better yields, he says.

While the team used ultrasound in the current study, Sijbesma envisions the chained catalysts being embedded in materials such as a coating on a car or a building, where the actual force of a scratch would release the catalyst and the material would automatically heal.

The findings could also be applied to large- and small-scale fluid operations where the force of sending a fluid through a jet spurs the liquid to solidify. Dyes could be incorporated into materials so they change color where the catalyst has been active, alerting a biker to weak spots on a helmet, for example.

Discovering that force applied to polymer chains could be used to control a catalyst was particularly exciting, says Sijbesma. “I had had this in my mind for quite a few years.”