From Metal Bars to Candy Bars

Materials scientists turn to what you're eating and how you eat it

When Peter J. Lillford’s two children were young, he saw no problem with the kids spitting out tough pieces of meat during dinner. Instead of withholding dessert until they cleaned their plates, Lillford turned his kids’ finicky eating habits into a teaching tool. Out came the tweezers so the family could dissect the offending mouthfuls.

In effect, Lillford was bringing his work home. As a food chemist at Unilever Research in Bedford, England, he investigates what makes different morsels cook, feel, and taste the way they do. He and other food-focused materials scientists treat those morsels the way metallurgists treat a piece of metal. It’s probed and prodded, tested for mechanical properties such as fracture and flow, analyzed with powerful microscopy, and finally put through rigorous trials in the machine where it will eventually be used. For Lillford’s work, that’s the mouth.

There’s more science in food appreciation than the chemistry of what stimulates taste buds. Consider the research behind designing creamier varieties of butter substitutes or keeping potato chips consistently crisp. Currently, this work relies heavily on trial and error and the imperfect standards of human testers.

That’s changing, however. Recent work by Lillford and other researchers is unraveling various foods’ hidden internal structures and uncovering the detailed physics that underlies, say, why we enjoy the texture of some chocolates more than others. That kind of knowledge may help innovators bypass much of the current hit-or-miss process and more directly devise recipes for appealing new foods.

Changing tastes, new options

There are many incentives for making the food-invention process more efficient. For one, “consumers don’t stand still,” says Athene M. Donald, a food physicist at the University of Cambridge in England. People’s tastes and demands change. Food suppliers strive to win market share by satisfying those fickle demands or by offering attractive new options.

As people work and travel more, for example, they demand a greater variety of prepared foods, says Donald. Consumers also want some traditionally seasonal foods, such as strawberries, plums, asparagus, and lettuce, to appear in grocery stores all year round. To make these products crispy, moist, and fresh tasting, even in the dead of winter, companies need to develop methods of producing and packaging them that retain their structural and textual properties.

Furthermore, materials scientists need to be aware that new packaging methods may raise issues of foodborne disease, says food scientist Peter Schroeder, past director of the Institute of Food Research in Norwich, England. For example, the controlled-atmosphere plastic bags used for ready-to-eat salad mixes may not subdue bacteria as well as older techniques, such as canning and pickling, he says in the December 2000 issue of the MRS Bulletin, published by the Materials Research Society.

Because of this risk, food producers must carefully examine how microbes behave on products packaged in new ways, agrees Donald. Such analysis requires understanding food’s microscale structures and how they might affect microbial survival.

A further incentive for food materials research: Although a company developing a new food product can train teams of testers to identify subjectively the crispness of a cracker or the creaminess of a custard, the industry lacks quantitative measures that directly correlate with these qualities.

More objective standards, such as specified microstructures, might help create consistent textures, say researchers. Then, they could design foods that will, for example, fracture with the desired crunch.

Designing new foods

To take a materials-science approach to designing new foods or improving old ones, researchers need to learn how to predict the changes that will take place in a food’s mechanical properties and structure when it is heated, cooled, pressed, mixed, extruded, and otherwise processed.

This challenge becomes even more complicated when processing food products on industrial scales. Stirring a pot on a stovetop or a beaker on a Bunsen burner is not the same as mixing ingredients in a 100-gallon vat.

“If you say that cooking is an art, the industry has to translate that into processes where they produce tons and tons and tons,” says chemical engineer Anne-Marie Hermansson of the Swedish Institute for Food and Biotechnology and the Chalmers University of Technology in Göteborg, Sweden.

Compared with many of the metallic, ceramic, and other substances that materials scientists study, foods usually contain much more water and are less stable, notes Donald. Furthermore, these foods have complex structures that range in size from molecules to mouthfuls.

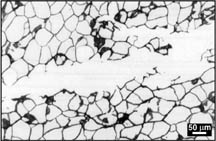

To take on this complexity, food-focused materials scientists are trying new microscopic and other analytical techniques, say Hermansson and her colleagues in the December 2000 MRS Bulletin. For example, they have observed under a microscope the mixing of gelatin and maltodextrin, which is derived from potato starch.

A series of pictures taken by the team shows the gradual development of an emulsion–a structure that can imitate fat when used in low-fat products such as spreadable margarine substitutes. Hermansson says that such images could

enable food scientists to predict what

microstructures, and thus textures, will form when they mix and process various ingredients.

Polymer physicist Richard Jones of the University of Sheffield in England works with similar mixtures. The goal for a low-fat spread, dessert, or salad dressing is to lose the fat but retain the creamy feeling, he says. Since the natural texture of whipped cream, for example, comes from networks of fat molecules, Jones–like Hermansson–tries to reproduce that structure with nonfat ingredients, such as water-soluble starch and gelatin that mimic the role of fat molecules. With the right temperatures and other processing conditions, the ingredients can form an interconnected network resembling the texture of natural fat in foods, he says.

Research has shown that different processing conditions can create different textures and mechanical properties, Jones notes. For example, a food researcher might want to create a continuous gelatin network that’s stable in a starch solution, he says. Or, for a smoother texture, the processing temperature could be changed to permit the gelatin to break up into small droplets.

In recent work, Jones’ team has found processing conditions that create something resembling a foam. The walls of the foamy structure contain the gelatin, he says, and each cell of the foam fills with a nongel solution, such as starch. Jones is particularly interested in the interface where the gelatin meets the nongelatin solution. Analyzing it will help him understand the mechanical properties of the material, he says, such as “whether it spreads like butter, the way it breaks, and the kind of texture it has.”

Chocolate treats

Food scientists are helping to design low-fat foods, but what about the ones we often feel compelled to eat despite their load of fatty molecules?

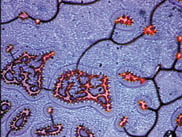

Here, the analogy with metallurgy is especially strong. Much like a metal alloy, a chocolate treat must undergo careful shepherding through complicated processing to achieve a desirable structure.

Cocoa butter, the yellow-white fat made from cacao beans, comes in several different crystal forms. Only one of these structures produces tempting, glossy, melt-in-your-mouth chocolate. Creating that structure requires a procedure called tempering–a series of steps with controlled heating, cooling, and mixing.

The other crystal forms don’t give consumers either the look or the taste that they demand in chocolate. For example, chocolate left on a kitchen shelf for several months morphs into a different crystal form, one with a familiar white film called fat bloom. This chocolate can taste gritty because some of its crystals don’t melt at the temperature inside a person’s mouth, notes chemical engineer Peter Fryer of the University of Birmingham in England. His work is sponsored in part by the chocolate company Cadbury, also in Birmingham.

Currently, Fryer and his colleagues are devising computer models for predicting the results of new food-processing methods to make them more efficient. In particular, these researchers are working on models to improve the tempering process used to make shells for filled chocolates, such as those in boxes of assorted candies.

Tempering makes chocolate shrink slightly and thus come away from its mold easily, says Fryer. It also prevents flavored fillings from breaking through their shells, which could contain soft spots if made from untempered chocolate. Moreover, the tempering process thwarts decay at the welded region between the bottom surface and the rest of a shell, he says.

By designing predictive models for processing foods such as chocolate, Fryer says, his team is acting just like materials scientists who make castings for a car. Metallurgists wouldn’t design an alloy for a machine part without knowing how the constituent materials would behave during the processing, he says.

However, there is one major difference between Fryer and traditional materials scientists–his lab is full of indulgences. Says Fryer: “I have [students] doing chocolate, beer, and ice cream.”

Crunchy vegetables

Meanwhile, at the opposite end of the food spectrum, Lillford analyzes why and how vegetables, such as carrots, crunch. In other words: What natural characteristics make them appealing for cooking or dipping?

Growers have bred most varieties of fruits and vegetables for yield–to produce big, fat carrots as fast as possible, says Lillford. His research is beginning to show that different varieties of carrots have a range of performances in the mouth or pan. Some kinds are worth growing, even though they have a low yield, because they’ll stay firm longer or cook up better, he says.

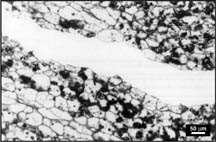

Lillford’s research group has looked at how cracks propagate through raw and cooked vegetables when you crunch into them. In fresh, raw vegetables, cell walls burst because they have high internal pressures. As a nascent crack grows, it blasts through the cellular structure at nearly the speed of sound.

When cooked, however, different vegetables fracture in different ways, Lillford finds. A crack breaks cells open in cooked water chestnuts. But in carrots, heating destroys the carbohydrate pectin that glues the cells together, so cracks skirt around cells of the cooked vegetable, Lillford says. These different styles of fracturing provide the diner with different gustatory sensations.

Since researchers already know a lot about the genetic control of plant cell walls, it would be possible to design plants with fracture characteristics and other structural qualities that make for good cooking and eating, says Lillford. He acknowledges, however, that such genetic engineering may not be welcome everywhere. Some consumers, particularly in Europe, have made it clear that they object to genetically modified foods. Lillford says that a more publicly palatable alternative for developing carrots with improved microstructures might be to use the traditional methods–selectively breeding plants that have the most desirable characteristics.

How people eat

Lillford points out that beyond determining the microscopic structures of edible stuff, there’s another significant piece of food-based materials science: studying how people eat.

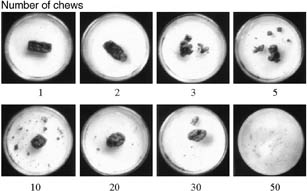

In experiments akin to the ones carried out by his kids around the dinner table, he asked a panel of initially horrified testers to spit out their food after a specified number of bites. The chewers then reported what the food felt like in their mouths and described how they used their tongues and teeth to chew.

Such studies have confirmed that the mouth first tears food into small pieces, moistens them, and eventually reassembles them into a ball for swallowing.

Still, that’s not nearly a sufficient description of eating for Lillford. “What does the tongue do? What do the teeth do? Does the mouth go up and down? How often?” Lillford asks. “We know an awful lot about how engines work, but the most common engine we have is a mouth, and we don’t know how it works.”

Lillford has now started to model the natural eating machine, using magnetic resonance imaging to observe volunteers’ mouths in action and employing ultrasound to map their tongues’ movements. “If you can analyze a machine motion–what a car engine or a vacuum cleaner does–can’t we model what the mouth does, in terms of motion and mathematics and forces and stresses and strains?” he says.

Particularly intriguing to Lillford is the rate at which the mouth moves food about. To physicists, most food falls into the category of soft solids, which are complicated and don’t always break up in simple ways. What’s more, he adds, much of an eater’s experience of these soft solids depends on the speed at which the mouth breaks up and moves the food.

“If we design another food, it might look all right, it might even crack all right, but the mouth will say, No, no, no, no,'” says Lillford. In other words, the new food might seem odd because of the speed at which the mouth has to work on it.

“I think that’s what’s happening when people say, ‘This biscuit is a bit sticky’ or ‘This butter is a bit waxy,'” he explains. “This has got to do not so much with the structure of the food itself, but how the structure changes at the rate that you move it about in your mouth,” Lillford conjectures. “Now, this is hard physics. Very hard physics.”

Too difficult, in fact, to solve by kids’ spitting out and poking at food around a dinner table. In any case, Lillford put a stop to those preliminary studies when his children started to conduct them in restaurants.

Ironically, however, the family was onto something. Recently, Lillford presented his work to a group of Cambridge mathematicians, hoping some of them might help him build a physical model of what goes on in the mouth.

During a coffee break, the mathematicians, in Lillford’s words, “spent all of their time eating biscuits and spitting them out.” Apparently, they had never considered precisely how they chew food and what happens to it when they do.

Lillford is pleased that some of the mathematicians have decided to help him tackle the problem of how food pieces assemble into a ball. But, even if they hadn’t, he’d still recall watching the university professors curiously spitting out their food during that coffee break as “one of the high notes of my career.”