Can Silicon Valley entrepreneurs make crickets the next chicken?

To feed the world, they'll need to scale up insect farming to make it efficient and sustainable

DOWN ON THE (CRICKET) FARM Making edible insects a consequential part of Western agriculture inspired the tech start-up Ovipost. CEO Trina Chiasson is flanked by chief science officer James Ricci and chief technical officer Tequila Ray Snorkel.

Brian Tietz

Trina Chiasson was raised in a log cabin, learned to spin plates in Chicago’s circus arts community, dreamed up a software company and three years later sold it to a bigger company. Her next challenge: building a business, called Ovipost, that brings better technology to cricket farming.

“I didn’t know any cricket farmers growing up, I know you’ll be shocked to learn,” she says. Yet she’s jumped into this new frontier of insect agriculture and, she hopes, a more sustainable food system. It’s all about reinventing ranching, but with six legs.

Humans have had thousands of years, including at least 50 years of industrial R&D, to figure out how to raise chickens, pigs and cattle. Today’s insect farmers in North America and Europe are racing to catch up, mixing ancient herder–style insights about domesticating wild animals with computer-vision algorithms and robot design.

How to grow enough critters often gets overlooked in the buzz about insects as cuisine. There’s far more fuss about whether Westerners will join the rest of the world and swallow a bug. Yet it’s the behind-the-scenes inventions and decisions that will determine how environmentally gentle insect farming can be and whether insects become a weekly staple that a lot of people can afford or just a foodie indulgence.

Start-ups and incubators

Chiasson’s cricket leap into farming will at least use her skills with data. Her first start-up company, Infoactive, developed software to turn raw data into easy-to-grasp charts and graphs. After she and a business partner sold the company in 2015 to the data visualization company Tableau Software for an undisclosed sum, Chiasson spent two years researching and strategizing about her next venture. Raised by back-to-the-land parents in Maine, she became a vegetarian around age 11, but now, she says, “I regularly chow down on insects.”

Chiasson met her next business partner, entomologist James Ricci, in San Francisco at the world’s largest nacho festival. “To see if we could execute on program without killing each other,” she says, the two spent a month building a booth promoting edible insects. Their creation debuted at the 2017 Oregon Eclipse festival. The two pulled it off without fatalities, and went on to set up Ovipost in San Francisco.

Chief technology officer Tequila Ray Snorkel describes herself as “200 percent a city kid.” Homeschooled in Cincinnati with an interest in physics, she (her preferred pronoun) worked on automated prosthetics in college and then took her mechanical engineering degree to the biotech company Synthego in Menlo Park, Calif. She’s been known to engineer provocations as well, such as strolling the streets in glitter to interview passersby on sensitive subjects. One outfit Snorkel devised was two pairs of bright yellow pants, the top one re-engineered so pant legs became sleeves. Chiasson saw Snorkel wearing it in a drag show and complimented her creativity — one of the more unusual ways to land a tech job.

Ovipost got an early boost from the iconic Silicon Valley start-up incubator Y Combinator, which nurtured Dropbox and Airbnb. Working out of two shipping containers, one piled on top of the other to make the most of a small footprint at San Francisco rents, the company started by automating the tedious, time-sucking management of cricket egg laying and egg counting.

Normally, farmers provide romantically moist peat moss for cricket mating, and count the offspring by coaxing them into measuring containers. Snorkel described it as “like convincing a few thousand tiny toddlers to take a bath.” Ovipost developed shortcuts, and for its Y Combinator finale pitch session, the company revealed a million cricket eggs swirling in a snow globe.

Less labor-intensive counting is just a first step in bringing down production costs, which, Chiasson says, “are way too high to be economically feasible in our current food system.” Compared with the low cost of raising industrial chickens, she says, producing crickets is “not even close.” Those production costs explain why a pound of boneless chicken breast retails for a little more than $3 versus $15 for a pound of food-grade crickets from the Armstrong family farms in Louisiana and Georgia.

When I heard that Ovipost’s Silicon Valley tech entrepreneurs had bought an old cricket farm in rural Florida, I was baffled. This move sounded like a pitch for a sitcom, a la Green Acres.

The Lazy H has been a cricket farm for about 30 years. It markets live crickets to reptile keepers and pet stores. The farm sits on what’s literally named “A Road” (it runs parallel to “B Road”) in the small town of LaBelle.

Snorkel the city kid makes the most spirited case for the surprising move: Designing tech for crickets needs crickets. The best way to test new automation tech is to put it into the hands of skilled workers with realistic conditions and volumes. That this testing facility happens to be a real farm paying its own way makes buying into LaBelle “almost a no-brainer,” she says.

Swerve

Driving along A Road with its solid walls of greenery, I overshoot the Ovipost mailbox, despite the clear markings. In my head, the word “farm” still begs for a pasture, a fence. But insect farms in the United States are indoor affairs, less Old MacDonald and more server farm.

When I nudge the car down a long driveway through yet another great billow of twisted oaks and blunt-leaved shrubbery, I reach a string of trailers and oversized red sheds. Inside, various creatures by the thousands are grazing, mating, fighting. But outside, it’s quiet. I could be parking in front of a bank.

The biggest miniherds at the Lazy H are the house crickets, and Snorkel leads me into a barn full of juvenile crickets. It’s a wide, long room with big plastic bins sitting edge to edge in rows down the middle and along the sides. A radio is playing, but I don’t hear crickets. (When the juveniles grow up, Ricci tells me later, the cricket chorus will be a day and night affair.)

The bins look like giant, sawed-off plastic milk jugs. They were once fertilizer containers, plentiful in agricultural LaBelle and the brainstorm of one of the farm’s earlier owners. Each bin could swallow a minifridge without a burp.

Around the inner perimeter of each bin, workers have stuck a wide stripe of slick, brown packing tape. It’s the insect farm version of split rail fencing, a stripe that’s just too slippery for crickets to cross. These strips need replacing after several weeks, one of many labor sucks at the farm that Snorkel is trying to improve on. The Ovipost crew scoured hardware stores for slippery spray-on coatings that would be much simpler to apply. The winner was a can of Krylon appliance epoxy, available for $3.50.

Now I learn something about innovation — location, location. The spray worked beautifully in San Francisco, Snorkel says, but it needs to be retested here. Florida humidity, the fertilizer bins and many more factors are different. Not until a few sprayed bins have efficiently fenced several generations of crickets would Snorkel deploy her epoxy brainstorm.

Below the fencing, I see stacks of egg separators propped around the edges. These grayish, cardboardlike rectangles with deep dents to hold chicken eggs safe and upright have become the industry standard for sheltering crickets. I see crickets tucked into the indents and huddled just under the lips.

Are there maybe … several hundred crickets in the bin? I ask. A woman working nearby laughs, with maybe a touch of farmer pride. There are thousands in just that one bin. Now I am impressed. Herding crickets this densely takes a cricket whisperer, and her name is Maria Mendieta. She’s been at the farm for 17 years and counts as one of its greatest assets. What she does “is magic,” Snorkel says. “I can’t tell you how to make this work.”

Snorkel points out a metal cart heaped with trays, unremarkable as far as I can see, that a man is pushing down one of the aisles between bins. When the Ovipost crew arrived with their Silicon Valley dreams, the thing that really cheered the workers, and certainly improved efficiency, was no more involved than replacing the balky, sticking wheels on this old cart.

In this kind of farming, simple, operational improvements will be just as important as the fancier tech, Snorkel predicts. Back when steam-powered factories were switching to electricity, for instance, a central steam boiler no longer constrained the positioning of the machines. The new electrical equipment added flexibility. Managers who experimented with factory layout saw big improvements in efficiency.

Setting up assembly-line flows and building some simple work stations, Snorkel says, “I definitely feel rooted in the first industrial revolution.”

Imagining Tequila Ray Snorkel as a rebooted Henry Ford, I follow her to a cricket breeding area, where females lay eggs in make-do, metal baking pans filled with moist peat moss like lumpy cake mix. From here, the egg pans get moved into what looks like a decent-sized heated closet with flypaper strips curling down from the ceiling. Snorkel points out that the racks holding the pans stand with their feet in little dishes of water to repel ants. Insect pests bedevil all kinds of farms, but they’re a special menace at insect farms because pest control can kill the livestock too.

When I e-mail later to ask what engineering might someday do to cut labor costs, Snorkel imagines “Willy Wonka’s cricket farm.” In rows of warm, humid tanks stacked higher than a farmer can reach, “a laboratory-crafted little Tide pod of just the right number of eggs for each container hatches out soft white nymphs.” These young crickets would grow up on processed human-food waste delivered by conveyor belt and water flowing by in a trough. After a month with no human intervention, the bins would tip onto conveyor belts, sending the insects to be sorted.

Not the basement

Crickets already thrive in basements without help from humans. Yet I’ve heard cricket farm consultant Kevin Bachhuber of Madison, Wis., get hearty applause just for the title of his talk: “Crickets are stupid, and will drown themselves if possible.”

So how hard is cricket farming? I ask him by phone. “Hard enough that my full-time job is helping other people figure out what went wrong,” he says.

Bachhuber started his own farm in Youngstown, Ohio, in 2014, but has since closed it. His was the first to pass U.S. government inspection for growing insects for people to eat. But soon enough, over 19 days, his crickets died, about 6 million of them.

Crickets aren’t the easiest or, he thinks, the best-tasting insects, but they’re a major seller for many of the 20 to 40 U.S. farms that Bachhuber estimates are selling insects for human food. In early April, his database listed some 540 U.S. businesses related to insect agriculture, and he’s sure he’s missing some.

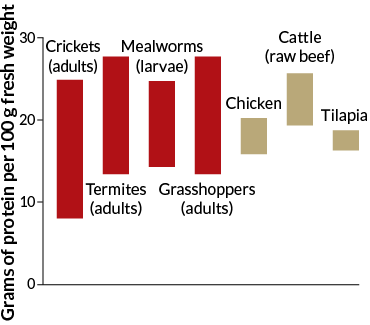

The edible insects market was estimated at over $55 million in 2017 by Global Market Insights, of Selbyville, Del., which projects a burst of growth ahead. Interest boomed after a 2013 United Nations’ Food and Agriculture Organization report, which made the case for insect farming as a way to meet the protein requirements of an expanding human population.

Farmers count

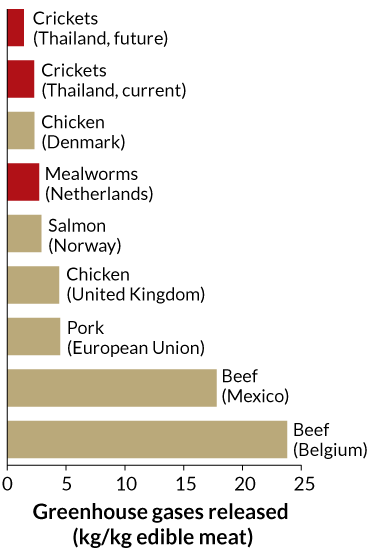

Insect farming often gets talked about as a single entity in discussions of environmental consequences, but that’s even more vague than saying “mammal farming.”

The list of edible insects stretches to over 2,000, and the bugs’ demands vary, says entomologist Åsa Berggren of the Swedish University of Agricultural Sciences in Uppsala. Some need meat to eat. Some, such as termites, produce methane, which is a powerful greenhouse gas.

Even in the same insect species at the same stage of life, environmental impact numbers can differ, Berggren and colleagues pointed out in the February issue of Trends in Ecology & Evolution. The few shreds of data on farming the house cricket (Acheta domesticus) suggest that the animals convert feed to body weight at rates varying from 1.6 (good) to 4.5 (almost as resource-hogging as pigs). What would be really sad, she says, is insect farming missing this chance to take the green and thrifty route.

A better way to judge farm impacts is to sum them all in a life cycle analysis, says Afton Halloran, a sustainable-food consultant based in Copenhagen. However, she knows of fewer than a dozen such analyses, and results differ.

Overall, the analyses suggest that what farmers choose to feed their insects is a big deal, Halloran says. A farmer might nudge the world in a better direction by feeding the microherd something that would normally be thrown away, for example, feeding chicken manure to black soldier fly larvae. Serving a different waste product, say beet pulp, also puts food waste to good use, but it racks up considerable environmental impacts. The larvae don’t grow well on the pulp, so they need a lot of it, plus heating to keep their metabolisms revved.

Also grown

Some farms have already diversified beyond crickets. Among its reptile foods, Lazy H raises discoid roaches, one of the few kinds that Florida allows people to cultivate on purpose. “We love the roaches,” Chiasson says. They withstand temperature fluctuations and shipping better than the crickets do. “They don’t smell as bad,” she adds. And when a roach dies in the tank, cleanup is easy: The other roaches eat most of it.

Can’t argue with that. The discoids live in a trailer, with worn blond wood paneling. A row of big fertilizer bins lines each side. Snorkel says that at night the whole trailer rustles.

Snorkel, too, clearly loves the roaches, calling them “relatable.” She points out some babies, a mature female and something that would make a fine half-moon pendant. It’s what’s left of a dead roach after the funeral lunch. Then she spots a female on its back, legs waving. “Contractions,” Snorkel suggests. This might be a roach prelude to releasing a brood of young. (Ricci, the entomologist, is skeptical of visible contractions but confirms that discoid eggs hatch in the mother’s body before birth.)

So that is how I find myself standing between a Silicon Valley software entrepreneur and a re-inventor of the pantsuit in an old trailer waiting quietly for a cockroach to give birth. This is about as far as you can get from Silicon Valley, but you can see the future from here too.

This article appears in the May 11, 2019 issue of Science News with the headline, “Down on the (Cricket) Farm: Can Silicon Valley entrepreneurs make insects the next chicken?”