You don’t have to be a caped superhero to stop a speeding bullet. Scientists have created a material that demonstrates how common plastics can bring projectiles traveling faster than a kilometer per second to a screeching halt. Similar materials might be used to make supertough lightweight body armor, or coatings to protect jet engine components or spacecraft from flying debris.

“This may provide a way to make new materials that are more durable,” says Catherine Brinson, a specialist in advanced materials at Northwestern University in Evanston, Ill., who was not involved with the work. “There may be applications for anything that is impacted at high speeds — body armor, satellites — anything that you don’t want destroyed.”

Experiments that shoot projectiles into the new material at breakneck speeds suggest that it goes through a weird, liquidlike phase that envelops the miniature bullets without cracking the material. The ballistics tests suggest that the material’s parallel layers of glassy and rubbery ingredients enhance its bullet-stopping power by 30 percent, an international team reports in the upcoming Nature Communications.

Some polymers such as hardened polyurethane are tangles of both hard and soft components at the microscopic level and are known for being exceptionally resistant to cracking under fire. Bullets shot into polyurethane disks are frozen in their tracks and sealed in place. But it hasn’t been clear how polyurethane captures speeding projectiles without cracking, says Ned Thomas of Rice University in Houston.

“Experimentally it works wonderfully. But theoretically, nobody knows why,” Thomas says.

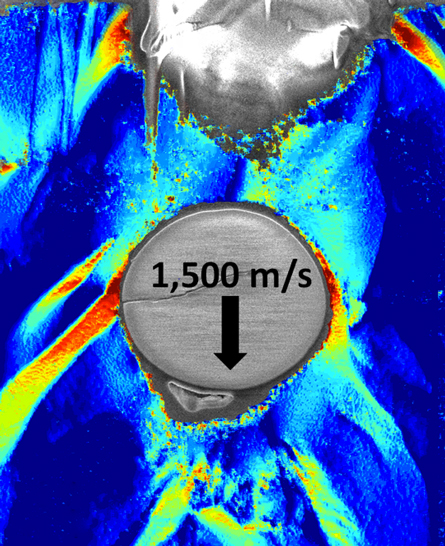

To better understand the ballistic properties of this common material, Rice research scientist Jae-Hwang Lee created a miniaturized system for studying the effects of impact. The target was a simplified, tidy version of polyurethane: a composite made by alternating orderly nanometers-thick layers of a glassy polymer (polystyrene) and a rubbery polymer (polydimethylsiloxane). Then the researchers used a laser to propel tiny silica beads about 3,400 nanometers in diameter into the target.

Bombarding the composite material with these nanobullets at speeds faster than those of a meteor hurtling through space revealed that the material undergoes a strange deformation on impact. The layers are compressed like a pancake, then kink and start to fragment. But instead of cracking, the layers then appear to melt and mix together, liquefied by the energy brought by the bead. The researchers estimate that energy imparted by the speeding projectiles briefly turns the material into a swirling, 3,000°-Celsius molten liquid that a millionth of a second later is solid again. Heating the material to such a degree on ordinary timescales would just burn it up, says Thomas.

“In the extreme conditions, the material behaves in ways that are unanticipated,” Thomas says. By figuring out how to manipulate its unconventional behavior, he says, “we can do extraordinary things.”