A new recycling process enlists the help of bacteria to turn the ubiquitous plastic PET into a biodegradable plastic that could replace the cellophane in food packaging.

The method, described in a paper posted online and set to appear in Environmental Science & Technology, could encourage more recycling of the billions of plastic bottles consumed every year.

PET, or polyethylene terephthalate, is one of the most

familiar kinds of plastic: Billions of pounds of PET bottles are sold every

year in the United States.

But less than a quarter of those are recycled, according to a 2006 study

by the trade group the National

Association for PET Container Resources .

Getting high-quality material — such as plastics suitable for packaging food or beverages —- back out of recycled plastic is more expensive than making virgin PET, so most plastic bottles are recycled into lower-grade, and less valuable, plastic.

But there’s only so much demand for lower-grade plastics, says microbiologist and coauthor Kevin O’ Connor of University College Dublin in Ireland. “The problem is that the market [for recycled PET] is saturated.”

New ways of turning PET into valuable materials, or “up-cycling” it, could create an incentive to recycle more of it, O’Connor says. Even better would be if the products of this recycling were biodegradable, as is polyhydroxyalkanoate, or PHA. “PHA demand could grow to a point where it could absorb a slice of the PET waste,” O’Connor says. “While PET to PHA is not the sole answer to PET recycling, it can be part of the solution.”

The approach could be promising if shown to be economically and environmentally feasible for large-scale production, says microbiologist Alexander Steinbüchel of the University of Münster in Germany. PHA has medical applications such as internal sutures, prosthetics and artificial tissue. If available in large quantities, it could be used as a biodegradable substitute for cellophane to, for example, package foods, Steinbüchel says.

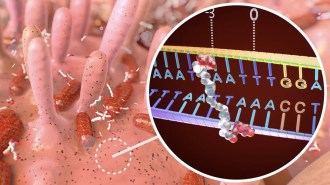

O’Connor and his team devised a two-step process to turn PET into PHA. First, his collaborator Walter Kaminsky of the University of Hamburg devised a way to break down PET by heating it. That produces a gas, a liquid and a solid. The solid, terephthalic acid, is a building block for the long polymer chains of PET. While PET itself is not biodegradable, some bugs could digest terephthalic acid, the scientists reasoned.

To find cooperative bacteria, O’Connor’s team went scouting for particles of PET in the soil near a plastic-bottle factory in Ireland. They found bacteria colonies growing on such particles, which meant they were probably feeding off terephthalic acid left over during the PET production process.

Sure enough, some of the bacteria they took back to the lab — in particular, certain strains of Pseudomonas putida — were able to digest the acid and turn it into PHA. O’Connor and his collaborators have used P. putida before, coaxing it into recycling polystyrene (SN 2/25/06, p. 117). At the same time, the researchers burned the gaseous and liquid byproducts to create a heat source for breaking down more PET.