Metal Makeover

Recasting metals as glass—for war and more

Some of the brass directing U.S. Navy research funding appears to have gone off the deep end: The Navy has been sinking serious money into the possibility of building future warships out of glass. Since the late 19th century, shipbuilders have opted for metals, mainly various grades of steel. Yet recently, military agencies have spent tens of millions of dollars on the concept of boats with glass hulls. As fractured as the idea may seem, it just might make maritime history.

There’s no plan to abandon the tried-and-true building of iron-sided ships. In fact, the new glass-bottomed boats being considered actually would be made of a kind of steel. That’s because under certain conditions, a metal’s orderly crystalline structure can be transformed into a hodge-podge of atoms that typifies glasses. In other words, the material becomes an amorphous or glassy metal, which can have remarkable strength or other desirable properties.

Earlier this year, two independent teams of materials scientists reported the first steels that are not only glassy but that also can be formed into relatively large pieces, a prerequisite for shipbuilding. Measurements indicate that those substances are up to three times as strong as conventional steels. What’s more, the glassy steels—even though they are iron alloys—exhibit little tendency to corrode, even in seawater, and are nonmagnetic at room temperature.

The upshot of these developments could be ships with thinner, yet stronger, hulls than conventional craft have. Less likely to rust than ordinary vessels, such ships also would require less maintenance, according to military sponsors of the research. Furthermore, because they would be nonmagnetic, the vessels could better evade detection and enemy mines.

Despite the promise of these new glassy steels, they’re not factory-ready yet, most notably because they’re too brittle. Ships made of the stuff would crack at sea, if they ever got there in the first place.

If efforts to overcome this flaw succeed, ships may prove to be only one small part of the future of such steels. Because the materials outperform ordinary steels in many ways, their potential uses span the range of structures, vehicles, equipment, tools, and weapons now made from conventional steel. What’s more, as the flagship for a whole new class of materials, glassy steel also may spur interest in other glassy metals, which are also known as metallic glasses.

“We could potentially move into the age of amorphous metals,” says Leo Christodoulou of the Defense Advanced Research Projects Agency (DARPA) in Arlington, Va.

Pedal to the metal

Since 1959, when Pol Duwez of the California Institute of Technology in Pasadena made the first metallic glass from gold and silicon, materials researchers have created thousands of glassy alloys from metals such as aluminum, nickel, titanium, copper, and iron.

Because those alloys combine traits of both glasses and metals, they often exhibit remarkable properties. For one, they’re typically two to three times stronger and harder than conventional crystalline metals are. Indeed, just last year a Japanese team reported making a cobalt-based glassy metal that seems to be the strongest metal ever made. That work by Akihisa Inoue of Tohoku University in Sendai and his colleagues appeared in the October 2003 Nature Materials.

Glassy alloys also appear to be tops among metals at recovering a shape after being deformed. “They make the world’s best springs,” says Gary J. Shiflet of the University of Virginia in Charlottesville. They also absorb energy from an explosion better than conventional metals do.

As a raw material, glassy metals offer another advantage over conventional metals: They behave as plastics do. Manufacturers can heat them to a viscous, taffylike state and inject them into molds to make objects of a specific size and shape, all in one step. Traditional ways of making parts out of ordinary metals often yield objects only approximately the size needed in a final product. Multiple steps, including expensive precision machining, are then required. The upshot could be a lot more metal replacing plastic, rather than the other way around, says Caltech metallurgist William L. Johnson, who trained under Duwez.

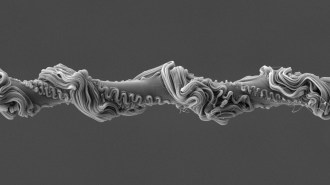

Many of the extraordinary properties of glassy metals result from their jumbled atomic structures. Ordinary metals dent, bend, stretch, and otherwise deform because the rows of atoms that make up the crystal lattices of metals can shift and rearrange.

However, because crystalline lattices don’t exist in glassy metals, there is no means for large numbers of atoms to shift in a coordinated manner. The result is a harder, stronger metal that can withstand much greater forces than ordinary metals.

The near immunity of many glassy metals to corrosion also appears to stem from their disordered structures. Corrosive agents such as acids, chlorine, or salts most readily attack metals where there are irregularities in the atomic structures at the materials’ surfaces.

Most crystalline metals are composites of many randomly oriented small crystal grains. At a metal’s surface, those boundaries are vulnerable to corrosion because of the irregular arrangement of the atoms located there, explains Atakan Peker, vice president of technology for Liquidmetal Technologies in Lake Forest, Calif., a company developing products from glassy metals. In metallic glasses, there are no grain boundaries, leaving few footholds for corrosion to begin, researchers suspect.

Glass ceiling

Despite the long history and many attractions of glassy metal, it’s been largely ignored by industry—and with good reason. For more than 20 years, no one could use it to make anything thicker than a coin.

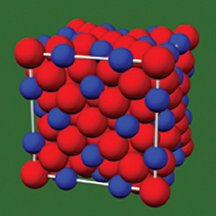

The reason has been the natural preference of most metals and metal alloys to form crystals, rather than glasses. As a metal cools from a liquid state, its atoms typically scurry into positions that balance the forces impinging on them, so the energy in the atomic bonds of the arrangement is small. Those arrangements are usually orderly and repetitious—crystalline.

Making a glass, however, requires freezing a substance before its atoms can find their way into cozy, crystalline arrangements. For common metal alloys, that means cooling the material at enormous rates in a process called quenching. Think of dropping a red-hot blob of metal into ice water.

Ordinary nonmetallic window glass can cool as slowly as a few hundredths of a degree Celsius per second without crystallizing, Johnson notes. However, for many years, the only metal alloys that researchers could convert to glass required instantaneous cooling, on the order of 1 million°C per second.

It’s possible to cool only extremely thin liquid films at such a rapid pace because heat can’t escape speedily enough from inside bulkier layers. Consequently, long after Duwez’ pioneering work, glassy metals provided only coatings and foils.

Because glassy metals’ magnetic fields can be reversed more easily than those of conventional magnetic metals can, glassy foils have long been used in a couple of commercial niches. Wound onto spools, they form the cores of energy-efficient power transformers. Also, some compact-music-disc distributors include strips of such foils in their antitheft packaging.

Beginning in the early 1990s, however, materials scientists began breaking through the glass ceiling of alloy size. To do so, they created novel alloy compositions that don’t crystallize as readily as simpler blends do.

In 1992, Johnson and Peker, who was then a Caltech graduate student, devised alloys of zirconium and titanium that could be cast in pieces more than a centimeter thick. That increase in bulk was modest, but it indicated that metallic glasses could be suitable for a wide range of industrial products (SN: 10/24/98, p. 264: http://www.sciencenews.org/pages/sn_arc98/10_24_98/bob1.htm).

“We made a [metallic] glass you could handle or process more like window glass,” Johnson says.

A few years later, Inoue and his colleagues unveiled palladium-based glasses as thick as bricks.

Liquidmetal Technologies now sells some items, such as cell phone cases and golf-club heads, made from the Caltech team’s zirconium- and titanium-based glasses. However, both titanium and zirconium are probably too expensive, as would be palladium, for making products outside some specific niches, scientists say.

Ship alloy!

Glassy steel is a different beast. Iron is so cheap that a glass made mainly from it could be economical in wide use, possibly wherever steel is used today, Johnson says.

In the May Journal of Materials Research, University of Virginia researchers Shiflet, S. Joseph Poon, and Vijayabarathi Ponnambalam reported breaking the 1 cm-thickness barrier with an iron-based glassy alloy including chromium, molybdenum, carbon, boron, and traces of the rare-earth element erbium. The Virginia team also found that other additives, such as the metals dysprosium and yttrium, yielded alloys particularly suitable for making large pieces. This summer, researchers at Oak Ridge (Tenn.) National Laboratory reported similar results with yttrium-containing iron formulations.

The Virginia researchers have developed a “material system that scores high on a lot of the requirements that a Navy vessel may need,” says Christodoulou, a materials scientist who heads a nearly completed, $30 million DARPA program that has funded the Virginia experiments as well as many other U.S.–based glassy-metals projects.

Despite researchers’ progress with iron alloys, the materials’ brittleness looms as a potential roadblock.

“The problem with the Virginia alloy is that it’s very strong but not very ductile,” contends Johnson, who has also been funded by DARPA. However, “that can be fixed,” he adds. Titanium-zirconium alloys developed at Caltech became more malleable and tough after their compositions were tweaked to permit some deformable crystals to precipitate in the cooling glass during fabrication, Peker says.

Christodoulou remains optimistic. “These materials can now be, for the first time ever, really considered as industrially and commercially viable,” he says.

Inoue disagrees. He notes that the concentration of iron in the new glassy-steel alloys is typically less than 50 percent—one of several factors that he says makes it “impossible” to create ductile forms of those glasses. Given the low iron content, Inoue also questions whether the alloys even deserve to be called steels, in which iron is usually the main ingredient by far.

Cooled cousin

Even as the metallurgists work to put some give in glassy steels, they keep coming up with novel alloys.

Liquidmetal Technologies is developing a glassy metal intended as a replacement for depleted uranium in armor-penetrating shells used by the Army. The alloy alternative is attractive because it avoids the controversial issue of radioactive contamination from the uranium. Like that heavy metal, the alloy under development keeps its penetrating edge as it slices through armor. “Very, very few metals can do that,” Peker says.

Copper-based glassy metals have also broken the 1-cm barrier. In a report in the June 18 Physical Review Letters, Johnson and his colleagues described a new, copper-based alloy that combines both ductility and extraordinary strength. Although conventional copper is too soft to typically serve as a structural material, the new glassy copper exceeds the strength of the best commercial steels made today.

The Virginia team has also come up with a titanium-based glass so workable that it can be bent, machined, and even threaded. The material’s surprising malleability suggests that some previously unknown mechanism for ductility may be at work, Shiflet says.

In these and other examples, researchers are thwarting the crystallization of familiar metals in order to launch a fleet of intriguing new materials.

Know Thy Enemy

Computer models begin to guide metallic glassmaking

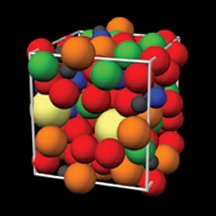

In a quest for better metal alloys, some scientists concoct mixtures of ingredients that aren’t intended to crystallize as normal metals do. Rather than forming into neatly organized lattices, the atoms in these mixtures are expected to pack together in a dense but randomly ordered arrangement—a glass. The resulting metallic glass often has superior properties, such as higher strength and corrosion resistance, compared with ordinary metals.

Crystallization is the enemy of these glasses. To get better at predicting which troublesome crystal structures might form, physicist Michael Widom of Carnegie-Mellon University in Pittsburgh and his colleagues have turned to computer calculations. In particular, they have determined the amount of energy released or absorbed when atoms of certain molten iron-based alloys, which several researchers are studying, assemble into various crystal formations.

Recently, the team identified glass-formation enemy number one: a complex crystalline structure with repeating, 29-atom motifs. Each cluster contains 23 iron atoms and 6 atoms of either carbon or boron. The calculations also show that adding yttrium atoms to the mixture should thwart the crystal structure’s formation.

Widom notes that Gary J. Shiflet and his colleagues at the University of Virginia in Charlottesville, who were aware of Widom’s findings, recently succeeded in making glassy steels by adding erbium, yttrium, or other trace elements to their iron-based mixture.

Moreover, says Widom, “the basic methods I’m using here could be applied to a whole host of different problems in metallurgy.” His team reported its findings in the Oct. 1 Physical Review B and an upcoming Journal of Materials Research.

Although no computer model has yet led directly to a new alloy, computational approaches such as Widom’s are going to play an expanding role in alloy development, Shiflet predicts.