Beer brewing is among the tastiest of chemical experiments. Problem is, the reactions that begin with the first manipulations of the barley grain don’t stop once the beer is in the bottle. The dynamic molecular world in all stored brews continues to alter flavors, sometimes overshadowing the tastes that a beer drinker loves with other flavors so offensive that they’re likened to skunk spray and cardboard.

The first push to delve into the mystery of beer flavor occurred in the mid-1970s, when a team of flavor chemists from 40 countries identified 800 chemical compounds in the beverage. These compounds—some individually, most in combination—contribute nearly 125 distinct flavors to beer. Brewers use the word flavor broadly, to include tastes, odors, and mouthfeel.

Today, says Morten C. Meilgaard, who chaired this international group, the total has risen to over 1,000 compounds. Studying the chemical constituents of beer is “like looking at the night sky,” he says. “The closer you look, the more stars you can see.”

About 40 flavors are common to the two broad types of beer, ales and lagers, which are defined by the yeast strains used to make them. Ales include pale ales, amber ales, and stouts, while pilsners and bocks are among the lagers.

Flavors defined as primary are present in concentrations at least double the minimum required for a person to recognize them. Ethanol, carbonation, and bitterness are primary to all beers, and many other beers have a few more primary flavors, such as the hop aroma in pale ales.

A host of other compounds contributes secondary flavors, such as banana or pear, and are present in amounts approaching or just above the detection concentration. Tertiary and background flavors are at concentrations below detection, but they can combine to add complexity to the brew.

Off flavors, however, can bluntly disrupt a beer’s bouquet. Most problematic are the stale flavor associated with aging and the skunky flavor that occurs when beer is exposed to light.

Researchers are continuing to tease out the chemistry behind unpleasant flavors. Recent work has provided more details about light-induced flavor and revealed an additional age-related flavor. Such work may someday lead to a brew that’s more chemically stable and thus has a stabler flavor, too. “People are always looking at ways to make [beer] better,” says Raymond J. Klimovitz of the Masters Brewers Association of the Americas.

Chemistry 101

In the first step of brewing, called malting, barley kernels are steeped, permitted to germinate, and then heated to temperatures as high as 110°C until dry. The higher the temperature, the more roasted, toffee-like flavors are present in the beer, says Charlie Bamforth of the University of California, Davis.

After malting, the barley is milled and mixed with hot water. In this stage, called mashing, barley enzymes convert the plant’s starch to sugar, primarily maltose.

Brewers next add hops (Humulus lupulus) to the liquid part of the mash, called the wort. The fruit of the hop plant contains nonbitter compounds called alpha acids.

As brewers boil the wort, the hops release these alpha acids. The heat alters their chemical structure, changing them into bitter-tasting compounds known as iso-alpha acids. The amount of hops added and the strength of the boil determine a beer’s bitterness.

Hops also contain oils, which contribute characteristic aromas to the brew. Depending on the hop variety, this aroma could be citruslike, piney, or herbal, says Karl J. Siebert of Cornell University.

The hop oils, however, easily vaporize during the boil. Lager brewers add another dose of hops at the end of the boil to boost aroma. Ale brewers wait until the end of the entire brewing process to add extra hops. This produces the stronger hop aroma common to many ales.

After cooling the wort, brewers add yeast (Saccharomyces cerevisiae) to start the fermentation stage. Ale yeast strains ferment at higher temperatures than do the lager strains.

As the yeast grows, it converts the wort’s sugars into ethanol and carbon dioxide. Bamforth describes ethanol’s flavor contribution as a warming characteristic, while carbon dioxide, through its interactions with pain receptors on the tongue, affects the mouthfeel of the beer.

Some of the yeast’s metabolic by-products add flavor as well. Esters, for example, lend fruity tones: Iso-amyl acetate smells of banana, and ethyl acetate smells of pear, says Bamforth. Higher fermentation temperatures ramp up ester production, so ales tend to have a fruitier flavor than lagers do.

After fermentation, the beer is stored at cold temperatures for periods ranging from a few days for an ale to a few weeks for a lager. Finally, the beer is filtered, further carbonated, and packaged.

Spoilers

Off flavors are the unintended consequences of beer chemistry. They’re the reason that beer often comes in opaque bottles and, even then, can’t be stored indefinitely. Brewers already have some ways to limit the development of off flavors during the brewing process, and recent research could provide additional flavor-stabilizing tools.

Brewing chemists attribute skunky flavor to 3-methylbut-2-ene-1-thiol, a constituent of skunk spray. This compound arises from a reaction that light triggers within the beer, and the resulting taste can overwhelm other flavors.

“Humans are very sensitive to this compound,” says Denis De Keukeleire of Ghent University in Belgium. 3-methylbut-2-ene-1-thiol is detectable in quantities as small as 0.004 microgram (µg) per liter. This amount can form in minutes when beer is exposed to bright sunlight, he says.

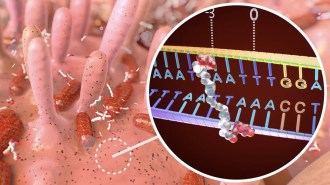

Riboflavin, a compound produced by yeast during fermentation, absorbs energy from light at wavelengths of 350 to 500 nanometers (nm). It transfers the energy to iso-alpha acids, the compounds that give beer bitterness. They then release free radicals—small, unstable chemical fragments—that react with sulfur compounds produced by the yeast. The result is the offending thiol.

Many brewers who want to prevent skunky flavor simply put their product in brown bottles, which block visible light of wavelengths under 500 nm. Some of the brewers who prefer to use clear or green bottles, which let in the problematic wavelengths, use hop pellets that contain chemically modified alpha acids. The altered structure, which contains additional hydrogen atoms, no longer forms 3-methyl–but-2-ene-1-thiol.

But research by De Keukeleire and his colleagues has revealed that this chemical modification of the iso-alpha acids doesn’t entirely prevent light-induced off flavors. The team reported in the March 9 Journal of Agricultural and Food Chemistry that the free radicals can still react with other sulfur compounds, creating flavors reminiscent of rotten eggs.

De Keukeleire’s group is now working on a fully light-stable hop product that diverts energy from the iso-alpha acids and toward hop compounds that won’t alter the flavor.

Beer flavor also deteriorates with age, and the older a beer is, the staler it tastes. Many brewers attribute stale, cardboard flavor to trans-2-nonenal. People can taste this compound at concentrations as low as 0.035 µg per liter, but it can reach 0.5 µg per liter of beer after 3 to 5 months of storage at room temperature.

The primary chemical pathway to stale flavor remains elusive. Oxidative reactions can produce this flavor, so brewers assiduously monitor the oxygen level during the brewing process, keeping it at or below 0.1 milligram per liter, Bamforth says.

Stale flavor isn’t entirely the fault of oxygen, however. In 1999, Belgian researchers discovered a nonoxidative mechanism behind the development of trans-2-nonenal.

Now, Danish researchers have identified a barley enzyme that converts trans-2-nonenal into nonanal. While too much of this compound would add an unpleasant, astringent character to the beer, its detection concentration is 150 times that of trans-2-nonenal, says Gustav Hambraeus of the Carlsberg Research Center in Copenhagen.

The team suggests in the Nov. 2 Journal of Agricultural and Food Chemistry that it may someday be possible to select barley varieties with enhanced activity of the enzyme, either by identifying plants with mutations in the enzyme’s gene or by genetically engineering plants to reduce the amount of trans-2-nonenal in the malt.

But cardboard is not the only off flavor that develops with age. Bart Vanderhaegen of Katholieke Universiteit Leuven in Heverlee, Belgium, and his colleagues have discovered that furfuryl ethyl ether contributes an unpleasant “solvent” or “chemical” flavor with age, primarily in ales. The concentration of furfuryl ethyl ether increases gradually during aging. It can reach its flavor threshold, about 6 µg per liter, in beer stored at room temperature for a month or so and can reach an overpowering 200 µg per liter after 6 months, says Vanderhaegen.

In the Nov. 3, 2004 Journal of Agricultural and Food Chemistry, Vanderhaegen’s team detailed how furfuryl ethyl ether forms. Its precursors are ethanol and furfuryl alcohol, which mainly derives from reactions between amino acids and sugars in the boiling wort.

Because beer is slightly acidic, its furfuryl alcohol can pick up an extra proton, explains Vanderhaegen. It then reacts with ethanol to form an intermediate compound, which splits off water and another proton to become furfuryl ethyl ether.

The researchers discovered that boiling the wort at higher temperatures and for longer times produced more furfuryl alcohol. If brewers reduce the heat applied, says Vanderhaegen, they can decrease the amount of furfuryl alcohol in the wort and, therefore, the amount of furfuryl ethyl ether that forms in the stored beer.

The customer, too, has a part to play in extending a beer’s life. “The most important way to slow down aging is to store beer at cold temperature,” says Vanderhaegen. “Brewers can’t control that.”

Heat speeds the reactions that produce stale flavors in stored beer. “You can ruin the flavor in a week,” says Siebert, by storing beer in a hot garage. Most brews, kept at room temperature, can be expected to keep their good flavor about 3 months, he says.

But for the best taste, keep storage time to a minimum. “The fresher the beer, the better it’s going to be,” Klimovitz says.

Customer choice

The steps that a brewery takes to enhance certain flavors and limit others ultimately depend upon how the company envisions its brand as well as what taste consumers expect when they open a bottle. Beer of a given type shouldn’t be different with each batch. “A lot of what a flavor chemist does is making sure the flavor doesn’t vary,” Meilgaard says.

This is a challenge not only during the brewing process. “Depending on the weather and the harvest, the malt and the hops will be different—a variation you have to account for every year,” Meilgaard explains. Brewers spend a great deal of time tasting their product to make sure that the flavor remains the same in the face of new ingredients and even new equipment.

While sameness is prized in individual types of beers, the unprecedented number of beer styles available today indicates that both brewers and drinkers celebrate variety. They can choose light or dark, mild or bitter, and varying aromas of hops or fruit.

Bamforth says that he chooses beer according to the place and the time: “If I’m in England, I like to drink English ales, and if I am at a baseball game, I would drink a Bud.”