Recyclable superplastics made with old chemistry

Two materials — one strong, the other self-healing — are the first easily recycled high-performance polymers

With an accidental tweak to a classic chemical reaction, scientists have created the first easily recyclable forms of mighty plastics. The discovery provides the potential to lower costs and reduce waste of everyday products, researchers say.

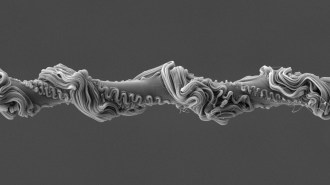

The two new nitrogen-containing materials, a superstrong plastic and a squishy, self-healing gel represent new types of thermosets, which are heat resistant and highly stable polymers. Thermosets are widely used, from automobiles and aerospace equipment to electronic devices, and are difficult if not impossible to recycle. But unlike other thermosets, the new polymers easily break down into their original components, ready to reassemble into something new.

Recycling these plastics is simple, says polymer chemist Jeannette García of IBM Almaden Research Center in San Jose, Calif. The process involves a splash of a liquid at a specific pH, she says. “This is a completely different paradigm for recycling.”

Recycling methods for standard plastics like water bottles often involve melting the polymers at very high temperatures, which tends to damage the chemical building blocks and change the polymers’ properties. With the new plastics, García says, researchers completely destroy and rebuild the material. “What you end up doing is undoing these bonds that have formed,” she says.

Those critical bonds weren’t carefully crafted with laborious research, but instead were created by serendipity, García says. While cooking down plastic water bottles for a chemical recipe she was testing, García missed a step. Despite the error, a hard chunk of plastic crashed out of the reaction in her flask. After smashing the glassware to retrieve the mysterious material, García found a nearly unbreakable rock of thermoset that was stable at temperatures up to around 300° to 350° Celsius.

Using computations to understand the reaction that formed the polymer, García and colleagues realized that the chemistry is a simple revision of an old reaction. For years, chemists have known that combining nitrogen-containing molecules called amines with formaldehyde creates hexagon-shaped rings of carbon and nitrogen, called triazines. But by fortuitously adding a double amine — one that has two nitrogens — to the formaldehyde, García’s team created triazines that could link together into a three-dimensional network, forming a polymer with superpowers. The results appear in the May 16 Science.

“The formaldehyde-amine reaction is one of the oldest used in polymer engineering,” says organic chemist Bert Meijer of the Eindhoven University of Technology in the Netherlands. By using it to create novel, unique materials, the research “catches the eye of every materials chemist,” he adds.

In redoing the reaction, García and colleagues found that adding the formaldehyde and double amine together at cooler temperatures, around 50° C, creates a jellylike thermoset. When the team cut the gel apart and placed the chopped pieces together, they reformed into a seamless whole. Though the self-healing gel was shelf stable, when researchers washed it with a liquid of neutral pH, like water, it would disassemble.

When heated to about 200° C, the double amine-formaldehyde reaction forms the hard plastic García initially discovered. The hard plastic also breaks down with a wash, but it requires a very strong acid, at pH 2. This severs bonds between the triazines and the network crumbles to the starting material.

“What I think is so exciting about this discovery is it’s really forcing scientists to think differently about chemistry and to make the science of recycling more accessible,” says chemist Timothy Long of Virginia Tech in Blacksburg.