Engineers have long dreamed of equipping aircraft, bridges, and other structures with sensor arrays that would give advance warning of structural failures. Researchers now report an analytical technique that may distinguish real damage from ordinary variation. Such a method in airliners might one day help pilots preempt tragedies such as the crash of American Airlines Flight 587, which killed 265 people, says Douglas E. Adams of Purdue University in West Lafayette, Ind. The plane plunged into a New York neighborhood on Nov. 12, possibly because of mechanical failures.

Owners of high-rise buildings might also benefit from damage-detecting sensors that would make their buildings smarter (SN: 11/22/97, p. 328: http://www.sciencenews.org/sn_arc97/11_22_97/bob1.htm). For instance, were such systems in use in downtown Manhattan, engineers might have immediately cleared up questions about the degree of damage suffered by neighboring structures when the World Trade Center fell after the terrorist attacks of Sept. 11 (see Ripples Spread Wide from Ground Zero, in this weeks issue: http://www.sciencenews.org/20011124/fob1.htm).

Today, such early warning systems remain too error-prone for practical use. Adams and his colleagues have developed a means to analyze sensor readings more reliably. The Purdue team has implemented its method with clusters of sensors that measure a structure’s vibration and strain–the amount of stretching or compression of an object with respect to its original size.

Systems now under development often generate false alarms by misinterpreting benign changes–for instance, expansion or contraction of structural parts from temperature changes–as damage, Adams says. Systems also miss damage masked by readings that indicate routine changes in conditions.

Still in its early stages, the new method promises to reduce false readings, Adams claims. By comparing measurements from clusters of sensors in a structure, the method extracts mathematical patterns associated with normal, safe operation. To increase the method’s accuracy and efficiency, the program that does this mathematical extraction incorporates information about which parts of the structure are most damage-prone. In effect, the system learns what patterns of readings correspond to a healthy structure so that it can recognize the deviations that indicate damage.

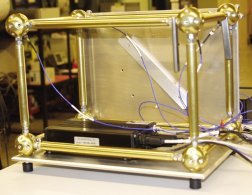

To test the new technique, the Purdue researchers, in collaboration with the Cincinnati-based company The Modal Shop, placed sensors on a sheet of aluminum.

They then vibrated the metal with a heavy-duty buzzer to simulate flight and other operating conditions of an aircraft. Finally, they squeezed the vibrating metal at various places with a clamp to simulate damage to the object. The system both recognized the clamping and pinpointed it relative to the sensors’ positions, the team found.

Even when the researchers varied the amplitude of the vibrations and the metal’s temperature, the technique still extracted the same abnormal pattern of sensor responses caused by the clamp. The team also tested a vibrating helicopter fuselage suspended from a ceiling.

“We proved that the technique works for detecting, locating, and quantifying the damage” even as operating conditions shift, Adams says. He plans to present the group’s results next month in Edinburgh at the International Conference on Smart Technology Demonstrators and Devices.

Adams and his collaborators are “building the foundation of a new approach to vibration monitoring,” comments Lawrence C. Freudinger of the NASA Dryden Flight Research Center in Edwards, Calif. The investigators intend to test the system on an aircraft in flight.